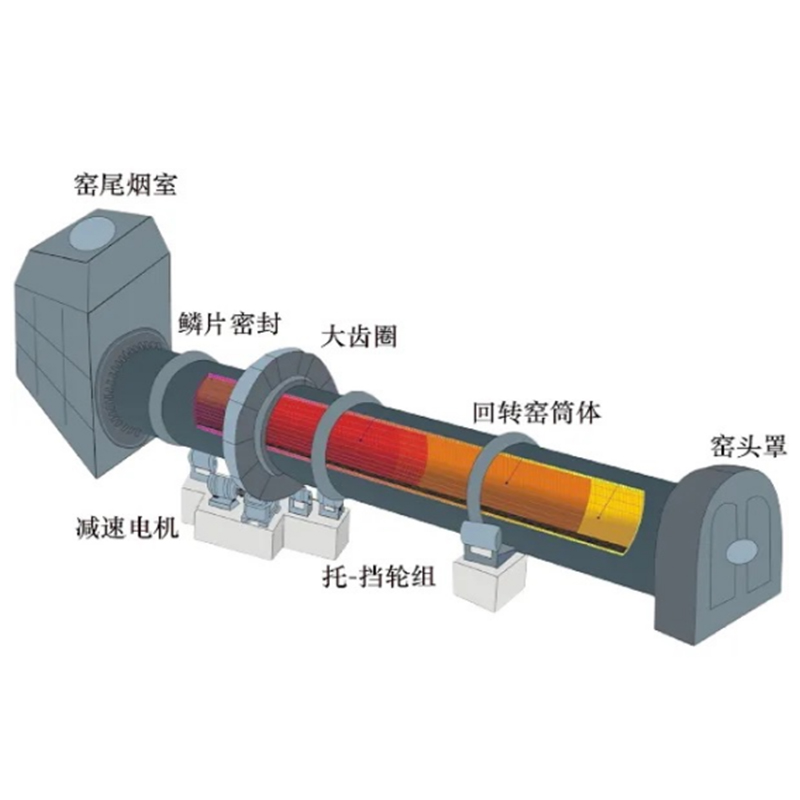

Device overview

The structure of the titanium dioxide calcining kiln is similar to the rotary kiln in the alumina, cement and other industries. Three pieces of rectangular wheel belts are sleeved on the cylinder body to be supported on each gear support device. A large ring gear is fixed on the cylinder near the intermediate belt with a tangential spring plate, and a small gear meshes with it at the lower 300 position. During normal operation, the main drive motor transmits power to the open gear device through the main reducer to drive the rotary kiln.

The use of titanium dioxide

Titanium dioxide ( titanium dioxide ) is an important inorganic chemical pigment whose main component is titanium dioxide. The production process of titanium dioxide has two process routes: sulfuric acid method and chlorination method. [1] It has important uses in coatings, inks, papermaking, plastic rubber, chemical fiber, ceramics and other industries.

Equipment composition

Titanium dioxide rotary kiln is composed of cylinder body, wheel belt, supporting wheel, blocking wheel, transmission device and kiln head and kiln tail sealing device.

Titanium dioxide rotary kiln process

The main working principle of the titanium dioxide kiln is as follows: the filtered titanium dioxide hydrolyzate filter cake is input into the tail end of the titanium dioxide rotary kiln with a certain slope and slowly rotating (the high end of the cylinder), and the direction of the kiln head (the lower part of the cylinder is low). The combustion and mixing chamber at the end) blows clean flame and hot air into the kiln to dehydrate and calcine the filter cake. The hydrolyzed titanium dioxide filter cake after dehydration and calcination at a high temperature above 1000 °C is tumbling in the circumferential direction and moving in the axial direction (from the high end to the low end) with the help of the inclined titanium dioxide rotary kiln body to continuously complete the process of dehydration and calcination. . Finally, it enters the cooler through the double hydraulic flap discharge valve at the lower part of the kiln head cover, and the material after cooling and screening is the finished titanium dioxide.

|

Titanium dioxide kiln technical performance table Specification |

Basic parameters |

Motor power |

support |

wheel |

weight |

Dimensions |

Remark |

||||||

|

Rotating speed |

slope |

Yield |

quantity |

Bearing form |

quantity |

form |

long |

width |

high |

||||

|

r / min |

% |

t/d |

kw |

t |

m |

||||||||

|

Φ 1.8 × 28 |

0.504 to 1.51 |

3.5 |

|

30/10 |

3 |

scroll |

1 |

mechanical |

59.39 |

|

|

|

|

|

Φ 1.8 × 32 |

0.504 to 1.51 |

4 |

|

30/10 |

3 |

scroll |

1 |

mechanical |

62.45 |

|

|

|

With coal injection pipe |

|

Φ 1.8 × 45 |

0.66 to 1.98 |

4 |

|

30/10 |

3 |

scroll |

1 |

mechanical |

80 |

|

|

|

|

|

Φ 2.2 × 45 |

0.85 to 2.54 |

3 |

|

55 |

3 |

scroll |

1 |

mechanical |

142.65 |

48 |

6.5 |

5.0 |

|

|

Φ 2.2 × 32 |

0.4 to 1.2 |

3.5 |

|

30/10 |

3 |

scroll |

1 |

mechanical |

121.2 |

35 |

5.7 |

5.3 |

|

|

Φ 2.4 × 38 |

0.2 to 0.6 |

2.2 |

|

30 |

3 |

scroll |

1 |

mechanical |

141.94 |

|

|

|

Calcined Titanium Dioxide |

|

Φ 2.5 × 50 |

0.5 to 1.05 |

3 |

|

55 |

3 |

scroll |

1 |

mechanical |

180 |

|

|

|

With coal injection pipe |

|

Φ 2.5 × 60 |

0.3 to 1.0 |

4 |

|

55 |

4 |

scroll |

1 |

mechanical |

217 |

63 |

6.1 |

5.8 |

Without coal injection pipe |

|

Φ 3.0 × 40 |

0.5 to 1.5 |

3 |

|

75 |

3 |

scroll |

1 |

mechanical |

257 |

|

|

|

|

|

Φ 3.0 × 45 |

0.444 to 1.332 |

3.5 |

|

55 |

3 |

scroll |

1 |

mechanical |

200 |

47 |

6.5 |

5.9 |

|

|

Φ 3 / 3.6 × 60 |

0.7 to 1.35 |

3.5 |

|

80 |

4 |

slide |

1 |

mechanical |

310 |

|

|

|

|

|

Φ 3.6 × 50 |

0.686 to 2.06 |

4 |

|

160 |

4 |

scroll |

1 |

mechanical |

522 |

|

|

|

|

|

Φ 3.6 × 52 |

0.55 to 2.06 |

4 |

|

125 |

4 |

scroll |

1 |

mechanical |

395 |

|

|

|

|

|

Φ 4.5 × 100 |

0.856 to 2.57 |

4 |

|

2 × 200 |

4 |

slide |

2 |

hydraulic |

884 |

|

|

|

With coal injection pipe |

|

Φ 4.5 × 110 |

0.856 to 2.57 |

4 |

|

2 × 200 |

5 |

slide |

2 |

hydraulic |

912 |

126.1 |

9.5 |

8.5 |

With coal injection pipe |

Anhui *** Titanium Dioxide Co., Ltd. φ2.6×48m Titanium Dioxide Kiln