Ball mill can be used for many mineral grinding, such as gold ore, copper ore, iron ore and zinc ore and so on.

Energy-saving grate ball mill is easy to start and save energy up to 20-30%,

INPUT:0-50mm

OUTPUT:80-200Mesh

Application

Iron ore, copper ore, gold ore, manganese ore, cobalt ore, lead and zinc ore, bauxite ore, rare earth ore,

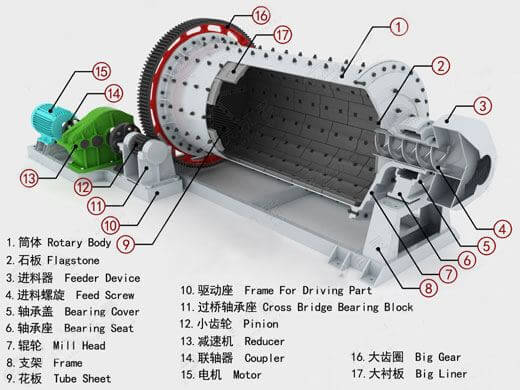

Its main component is a cylinder with bigger diameter and smaller length which can revolve via the transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded, because the falling course of iron balls and ores can produce huge falling impact and autogenous grinding. The continuous feeding of ores can create considerable pressure to make ores move from feed opening toward discharge opening. Finally, acceptable particles are discharged from the discharge opening. Acceptable ore particles are carried away by water by wet mill, or by air by dry mill. The discharge opening is equipped with a discharge grate, and the ore pulp horizon of discharge opening is low. These two factors prevent ores from being overly grinded, and iron balls from being dismissed. Under same circumstance, the processing capacity of energy-saving grate ball mill is bigger. Rolling bearings contribute enormous energy saving.

Product structure

|

Model parameters |

Cylinder diameter |

Cylinder length |

Volume |

Speed |

Abrasive load |

Motor |

Weight |

|

|

Power |

Speed |

|||||||

|

mm |

mm |

m3 |

r/min |

|

kw |

r/min |

t |

|

|

MQS1224 |

1500 |

3000 |

5 |

26.6 |

9 |

95 |

742 |

18 |

|

MQS1515 |

1500 |

1500 |

2.3 |

29.2 |

4.8 |

60 |

725 |

13.7 |

|

MQS1524 |

1500 |

2400 |

3.7 |

29.2 |

7.6 |

90 |

730 |

16.5 |

|

MQS1530 |

1500 |

3000 |

4.6 |

26.6 |

10 |

90 |

742 |

19.5 |

|

MQS2130 |

2100 |

3000 |

9.4 |

22.1 |

20 |

220 |

740 |

45 |

|

MQS2430 |

2400 |

3000 |

12.2 |

21 |

25 |

250 |

980 |

55 |

|

MQS2470 |

2400 |

7000 |

26.66 |

21 |

54 |

475 |

740 |

67 |

|

MQS2721 |

2700 |

2100 |

10.6 |

19.7 |

22 |

280 |

733 |

69 |

|

MQS2736 |

2700 |

3600 |

18.5 |

20.5 |

39 |

400 |

187.5 |

74 |

|

MQS2740 |

2700 |

4000 |

20.5 |

20.24 |

38 |

400 |

187.5 |

77 |

|

MQS2760 |

2700 |

6000 |

34.34 |

19.5 |

53 |

630 |

589 |

84 |

|

MQS2941 |

2900 |

4100 |

26 |

19.34 |

42 |

450 |

740 |

76.1 |

|

MQS3164 |

3100 |

6400 |

43.7 |

18.3 |

56 |

1000 |

167 |

141 |

|

MQS3231 |

3200 |

3100 |

22.65 |

18.3 |

46.9 |

500 |

167 |

109 |

|

MQS3236 |

3200 |

3600 |

26.3 |

18.3 |

54 |

630 |

167 |

116.94 |

|

MQS3240 |

3200 |

4000 |

29.2 |

18.2 |

60 |

710 |

980 |

121.4 |

|

MQS3245 |

3200 |

4500 |

32.9 |

18.3 |

68.5 |

800 |

167 |

126.23 |

|

MQS3254 |

3200 |

5400 |

39.4 |

18.3 |

81.6 |

1000 |

167 |

135.4 |

|

MQS3645 |

3600 |

4500 |

41.4 |

17.25 |

86 |

1000 |

167 |

153.1 |

|

MQS3660 |

3600 |

6000 |

54 |

17.3 |

112 |

1400 |

167 |

190.6 |

|

MQS3685 |

3600 |

8500 |

79 |

17.4 |

144 |

1800 |

743 |

260.89 |

|

MQS4060 |

4000 |

6000 |

69.8 |

16.0 |

126 |

1500 |

200 |

215.5 |

|

MQS4067 |

4000 |

6700 |

76 |

16.0 |

155 |

1600 |

980 |

235.2 |

|

MQS40×13.5 |

4000 |

13500 |

157 |

16.5 |

280 |

3300 |

980 |

284/375 |

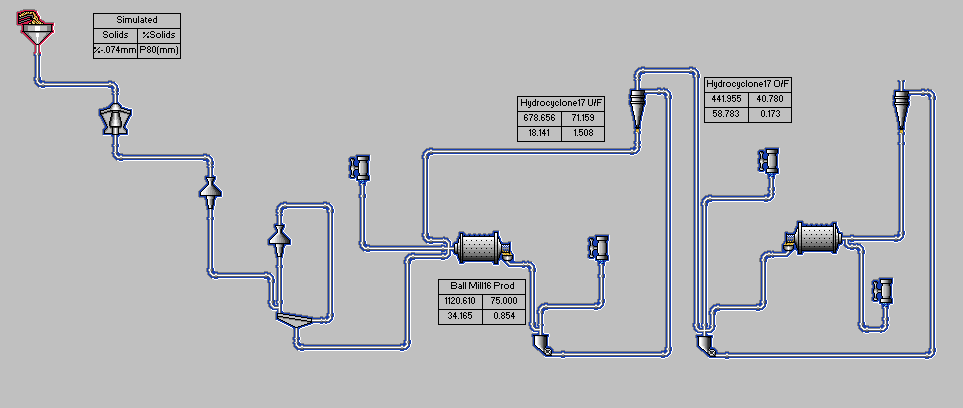

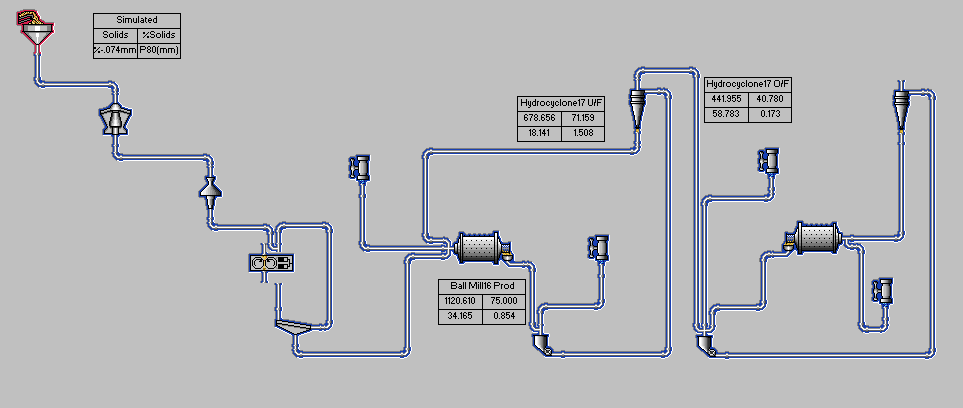

The mineral processing production line is composed of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, concentrator, dryer and other main equipment. The production line has the advantages of high efficiency, low energy, high handling capacity and economic rationality.

The production process of mineral processing line is as follows: the ore mined is initially broken by jaw crusher, and after being broken to a reasonable fineness, it is uniformly sent to the ball mill by elevator and feeder, which crushes and grinders the ore. After the ball mill grinding fine ore into the next step: grading. Based on the principle of different specific gravity of solid particles and different precipitation rate in liquid, the spiral classifier cleans and classifies the ore mixture. After washing and grading the mineral mixture through the magnetic separator, due to different specific magnetization coefficients of various minerals, magnetic and mechanical forces will be separated from the magnetic material in the mixture. After initial separation by the magnetic separator, the mineral particles are fed to the flotation machine and different drugs are added according to different mineral properties, so that the desired minerals are separated from other substances. After the minerals are separated, because they contain a lot of water, they must be concentrated by the concentrator and dried by the dryer.