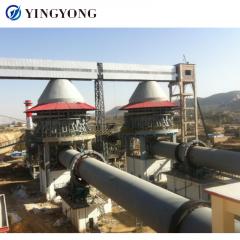

Rotary kiln preheater

Rotary kiln preheater

Product introduction

The main function is to make full use of the thermal enthalpy of raw materials in the hot gas flow discharged from the rotary kiln and the rotary kiln, to preheat and decompose part of the carbonates, and then enter the rotary kiln and continue to heat and decompose to complete the calcining of clinker. Therefore, it must have the following three functions: sufficient dispersion and uniform distribution of gas-solid phase, rapid heat exchange, and efficient separation

The main function is to make full use of the thermal enthalpy of raw materials in the hot gas flow discharged from the rotary kiln and the rotary kiln, to preheat and decompose part of the carbonates, and then enter the rotary kiln and continue to heat and decompose to complete the calcining of clinker. Therefore, it must have the following three functions: sufficient dispersion and uniform distribution of gas-solid phase, rapid heat exchange, and efficient separation

Structural features:

It is mainly composed of cyclone tube, air pipe, discharge pipe, decomposing furnace, lock air valve, spreader plate, inner tube hanging sheet, decomposing furnace and feeding room.

It is mainly composed of cyclone tube, air pipe, discharge pipe, decomposing furnace, lock air valve, spreader plate, inner tube hanging sheet, decomposing furnace and feeding room.

Working principle:

The material is lifted through the kiln bucket and enters the chute of part of the material on the top of the kiln. The rotary feeder enters the preheater at the end of the kiln from the feeding port on the c2-c1 air duct. The material in the updraft air duct is brought into the C1 cyclone tube. In the cyclone tube, the material is collected by the cyclone and enters into the c3-c2 air pipe through the C1 blanking tube. At the outlet end of the blanking tube, there is a charging device to evenly distribute the material in the updraft. In this way, the material and hot gas get full heat exchange. All processes above the C4 cyclone cylinder are similar to those described above. The decomposing furnace is a core equipment in the preheater system. It is equipped with four sets of coal spraying pipes, which are used to inject fuel into the decomposing furnace respectively with left rotation and right rotation. About 55-65% of the total fuel is burned in the furnace, which provides the ambient temperature for material separation. The fully heated and decomposed material enters the C5 cyclone cylinder with gas, and finally enters the rotary kiln through the feeding room. So the whole process is; Materials from top to bottom, high temperature gas from bottom to top, and the material heating and decomposition.

The material is lifted through the kiln bucket and enters the chute of part of the material on the top of the kiln. The rotary feeder enters the preheater at the end of the kiln from the feeding port on the c2-c1 air duct. The material in the updraft air duct is brought into the C1 cyclone tube. In the cyclone tube, the material is collected by the cyclone and enters into the c3-c2 air pipe through the C1 blanking tube. At the outlet end of the blanking tube, there is a charging device to evenly distribute the material in the updraft. In this way, the material and hot gas get full heat exchange. All processes above the C4 cyclone cylinder are similar to those described above. The decomposing furnace is a core equipment in the preheater system. It is equipped with four sets of coal spraying pipes, which are used to inject fuel into the decomposing furnace respectively with left rotation and right rotation. About 55-65% of the total fuel is burned in the furnace, which provides the ambient temperature for material separation. The fully heated and decomposed material enters the C5 cyclone cylinder with gas, and finally enters the rotary kiln through the feeding room. So the whole process is; Materials from top to bottom, high temperature gas from bottom to top, and the material heating and decomposition.

Feedback from contact with us

Related Product

Cement rotary kiln

Summary of the equipment

Cement rotary kiln belongs to building materials equipment class, is a kin...

Learn More>

Limestone rotary kiln

Use of lime

The uses of lime are very wide. Common in construction, building materials, metallurgy,...

Learn More>

Pellet rotary kiln

Equipment Overview

The pellets are roasted and consolidated in a rotary kiln.

Normal reside...

Learn More>