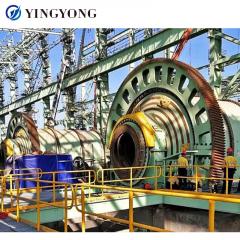

The wet ball mill for mining is divided into lattice ball mill and overflow ball mill according to different mining methods. It has the advantages of high crushing ratio, good reliability, strong adaptability and large processing capacity. It is widely used in mineral processing, metallurgy and construction,chemical and other industries, is the main equipment for grinding operations.

Application

Iron ore, copper ore, limestone, gold ore, manganese ore, bauxite, lead-zinc ore

Overflow ball mill is used in concentrator. The discharging is due to the fact that the hollow axis diameter of discharging end is slightly larger than that of feeding end, resulting in a certain inclination of pulp in the mill towards discharging end. When the height of pulp surface is higher than the lower busbar of inner diameter in the discharging inlet, the pulp overflows and discharges from mill. This is a non-forced high-level ore discharging, the discharging speed is slow, so the ore resides in the machine for a long time, the efficiency of grinding media is also low, so the overgrinding of the overflow ball mill happens very often, and the handling capacity is lower than the lattice type of the same specification. Generally, it is usually used for fine grinding or two-stage grinding.

Technical characteristics:

The transmission type of ball mill include edge drive, center drive, multi-point meshing edge drive, etc. The drive mode is asynchronous motor + reducer + pinion + big gear and synchronous motor + air clutch + pinion + girth gear.

*In general, the support mode of static and dynamic pressure bearings at both ends is adopted, and the fully closed self-aligning 1200-line contact'rocker-type'bearing is adopted. The support mode of static and dynamic pressure of single and double sliding or full static pressure support can also be adopted.

*The open girth gear is designed by the US AGMA standard, equipped with a reliable gear cover and an automatic glycerol spray lubrication device.

*Cylinder is the key part of the mill. The finite element analysis is carried out by computer to ensure the reliability of the mill.

*Large and medium mills are equipped with slow drive devices.

*Large and medium mills are equipped with lubrication stations of high and low pressure.

*Control and protection system is controlled by PLC

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

mm |

mm |

m3 |

r/min |

|

kw |

r/min |

t |

|

MQS1224 |

1500 |

3000 |

5 |

26.6 |

9 |

95 |

742 |

18 |

|

MQS1515 |

1500 |

1500 |

2.3 |

29.2 |

4.8 |

60 |

725 |

13.7 |

|

MQS1524 |

1500 |

2400 |

3.7 |

29.2 |

7.6 |

90 |

730 |

16.5 |

|

MQS1530 |

1500 |

3000 |

4.6 |

26.6 |

10 |

90 |

742 |

19.5 |

|

MQS2130 |

2100 |

3000 |

9.4 |

22.1 |

20 |

220 |

740 |

45 |

|

MQS2430 |

2400 |

3000 |

12.2 |

21 |

25 |

250 |

980 |

55 |

|

MQS2470 |

2400 |

7000 |

26.66 |

21 |

54 |

475 |

740 |

67 |

|

MQS2721 |

2700 |

2100 |

10.6 |

19.7 |

22 |

280 |

733 |

69 |

|

MQS2736 |

2700 |

3600 |

18.5 |

20.5 |

39 |

400 |

187.5 |

74 |

|

MQS2740 |

2700 |

4000 |

20.5 |

20.24 |

38 |

400 |

187.5 |

77 |

|

MQS2760 |

2700 |

6000 |

34.34 |

19.5 |

53 |

630 |

589 |

84 |

|

MQS2941 |

2900 |

4100 |

26 |

19.34 |

42 |

450 |

740 |

76.1 |

|

MQS3164 |

3100 |

6400 |

43.7 |

18.3 |

56 |

1000 |

167 |

141 |

|

MQS3231 |

3200 |

3100 |

22.65 |

18.3 |

46.9 |

500 |

167 |

109 |

|

MQS3236 |

3200 |

3600 |

26.3 |

18.3 |

54 |

630 |

167 |

116.94 |

|

MQS3240 |

3200 |

4000 |

29.2 |

18.2 |

60 |

710 |

980 |

121.4 |

|

MQS3245 |

3200 |

4500 |

32.9 |

18.3 |

68.5 |

800 |

167 |

126.23 |

|

MQS3254 |

3200 |

5400 |

39.4 |

18.3 |

81.6 |

1000 |

167 |

135.4 |

|

MQS3645 |

3600 |

4500 |

41.4 |

17.25 |

86 |

1000 |

167 |

153.1 |

|

MQS3660 |

3600 |

6000 |

54 |

17.3 |

112 |

1400 |

167 |

190.6 |

|

MQS3685 |

3600 |

8500 |

79 |

17.4 |

144 |

1800 |

743 |

260.89 |

|

MQS4060 |

4000 |

6000 |

69.8 |

16.0 |

126 |

1500 |

200 |

215.5 |

|

MQS4067 |

4000 |

6700 |

76 |

16.0 |

155 |

1600 |

980 |

235.2 |

|

MQS40×13.5 |

4000 |

13500 |

157 |

16.5 |

280 |

3300 |

980 |

284/375 |

|

Model |

|

|

|

|

|

|

|

MQY3245 |

3200 |

4500 |

32.8 |

18.5 |

61 |

630 |

|

MQY3254 |

3200 |

5400 |

39.5 |

18.5 |

73 |

1000 |

|

MQY3260 |

3200 |

6000 |

43.7 |

18.5 |

81 |

1000 |

|

MQY3545 |

3600 |

4500 |

41 |

17.5 |

76 |

1000 |

|

MQY3650 |

3600 |

5000 |

46.2 |

17.3 |

86 |

1250 |

|

MQY3660 |

3600 |

6000 |

55 |

17.3 |

102 |

1250 |

|

MQY3690 |

3600 |

9000 |

83 |

17.3 |

145 |

1800 |

|

MQY3862 |

3800 |

6200 |

64 |

16.8 |

118 |

1500 |

|

MQY4060 |

4000 |

6000 |

70 |

16.8 |

113.4 |

1500 |

|

MQY4067 |

4000 |

6700 |

78 |

16.2 |

138 |

1600 |

|

MQY4361 |

4270 |

6100 |

80 |

15.7 |

144 |

1750 |

|

MQY4385 |

4270 |

8500 |

110 |

15.7 |

205 |

2500 |

|

MQY4561 |

4572 |

6100 |

93.3 |

15.1 |

151 |

2200 |

|

MQY4564 |

4500 |

6400 |

97 |

15.1 |

134 |

1950 |

|

MQY4576 |

4500 |

7600 |

111.7 |

15.1 |

180 |

2200 |

|

MQY4669 |

4600 |

6900 |

105.9 |

15 |

185 |

2300 |

|

MQY4870 |

4800 |

7000 |

118.9 |

15 |

208 |

2500 |

|

MQY4883 |

4800 |

8300 |

138 |

15 |

240 |

3000 |

|

MQY5064 |

5030 |

6400 |

121 |

14.4 |

224 |

2600 |

|

MQY5067 |

5030 |

6700 |

123.2 |

14.4 |

227 |

3000 |

|

MQY5070 |

5030 |

7000 |

128.8 |

14.4 |

227 |

3000 |

|

MQY5074 |

5030 |

7400 |

136 |

14.4 |

240 |

3300 |

|

MQY5080 |

5030 |

8000 |

147.2 |

14.4 |

246 |

3300 |

|

MQY5583 |

5500 |

8300 |

182 |

13.7 |

296 |

4100 |

|

MQY5585 |

5500 |

8500 |

185 |

13.7 |

300 |

4500 |

|

MQY5588 |

5500 |

8800 |

191.5 |

13.7 |

335 |

4500 |

|

MQY6095 |

6000 |

9500 |

249.3 |

13 |

462.6 |

6000 |

|

MQY67116 |

6710 |

11570 |

385 |

12.5 |

625 |

2×4700 |

|

MQY73115 |

7315 |

11497 |

494.1 |

12 |

871.2 |

2×6750 |

|

MQY80120 |

8000 |

12000 |

570.5 |

11.5 |

1005.8 |

15000 |

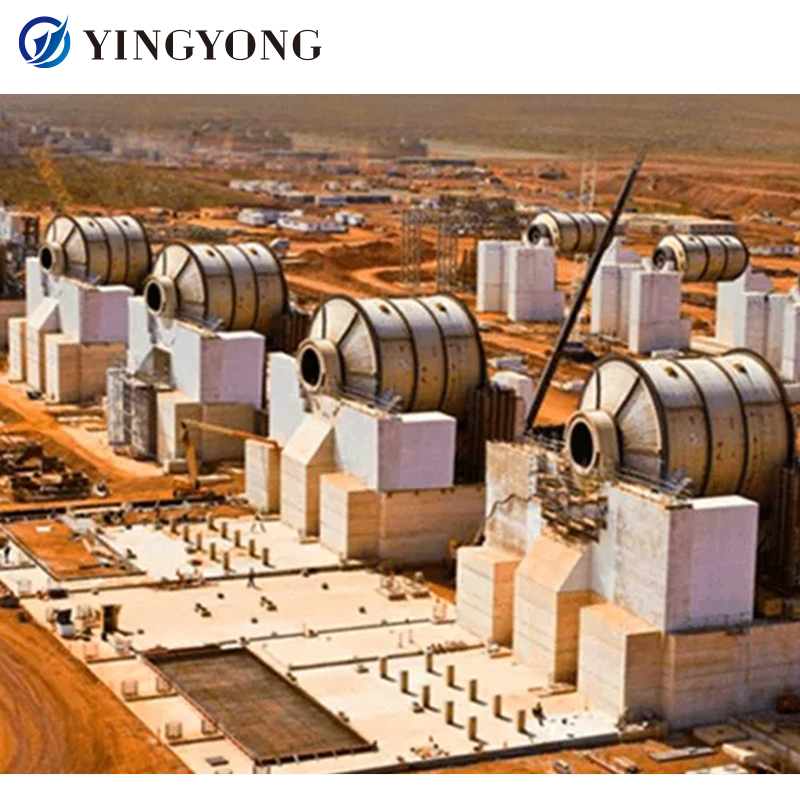

China Gold Group has signed an order contract for the largest dual-motor driven semi-autogenous mill and dual-motor driven overflow ball mill in China. The total designed power of the ball mill is currently the largest in the world. The equipment will be used in the Wunuuge Tushan Copper-Molybdenum Mine Project. The designed capacity is 35,000 t /d, and the maximum capacity can reach 42,000 t /d

Equipment parameters:

Aogenous tumbling mill: ouble motor-driven semi-autogenous grinding mill with diameter of 11× 5.4 meters, total power is 2 × 6343 kW

Duobaoshan, overflow type ball mill used for copper ore