Limestone ball mill is a new type of environmental protection equipment independently researched and developed by our company. It is the main equipment of the preparation system of limestone slurry and flue gas desulfurizer in thermal power plant. At the same time, also suitable for metallurgy, chemical, aluminum and other industries flue gas desulfurization agent preparation system.

application

mainly used for grinding cement clinker and other materials in building materials, metallurgy, electric power and chemical industry.

Product features

The product has the advantages of compact structure, convenient installation and maintenance, smooth operation, etc., widely used for crushing limestone, phosphate ore and other grindable materials of various hardness. Use performance to reach the domestic leading level; The equipment is easy to maintain and repair, and the worn parts are easy to replace.

Our company can design and manufacture various specifications of limestone mill and non-standard limestone mill according to the different requirements of users.

| 项目Item/规恪Spec.(m) | Φ1.83x6.4 | Φ2.2x5.4 | Φ2.4x5.8 | Φ2.7x6.0 | Φ2.7x6.5 | Φ2.9x6.5 | Φ2.9x7.0 | Φ3.2x6.4 | Φ3.2x7.0 |

| 工作转速 Speed (r/min) | 23.8 | 21.3 | 21.7 | 20.5 | 20.5 | 19 | 19 | 18.2 | 18.2 |

| 生产能力 Capacity (t/h) | 3~5 | 6~8 | 9~10 | 13~14 | 15~16 | 16 ~18 | 18 ~20 | 22~24 | 24 ~26 |

| 研磨体装载量 Grinding Media Loading (t) | 20 | 25 | 32 | 43 | 47 | 50 | 54 | 62 | 70 |

| 主减速机 Main Reducer | ZD60 | ZD60 | ZD70 | ZD70 | ZD70 | MBY560 | MBY560 | MBY630 | MBY630 |

| 主电动机 Main Motor (KW) | 210 | 280 | 380 | 570 | 570 | 630 | 630 | 800 | 900 |

| 总重量Weight (t) | 42 | 58 | 76 | 121 | 125 | 138 | 141 | 152 | 159 |

| 项目Item/规格 Spec. (m) | Φ1.83x7.0 | Φ2.2x7.0 | Φ2.4x7.0 | Φ2.4x9.0 | Φ2.6x8.0 | Φ2.6x10 | Φ2.8x9.0 | Φ3.0x9.0 | Φ3.0x11 |

| 工作转速 Speed (r/min) | 23.8 | 21.7 | 21.7 | 21.5 | 19.7 | 19.7 | 18.3 | 18.2 | 18.2 |

| 生产能力 Capacity (t/h) | 3~5 | 6~8 | 8~10 | 12~14 | 14~16 | 16~18 | 18~20 | 22~24 | 24~26 |

| 研磨体装载量 Grinding Media Loading (t) | 22 | 35 | 39 | 48 | 52 | 65 | 72 | 78 | 95 |

| 主减速机 Main Reducer | ZD60 | ZD70 | ZD70 | ZD80 | MBY630 | MBY710 | MBY630 | MBY800 | MBY800 |

| 主电动机 Main Motor (KW) | 245 | 380 | 480 | 570 | 630 | 800 | 900 | 1000 | 1250 |

| 总重量Weight (t) | 43.5 | 62.5 | 81 | 92 | 112 | 130 | 145 | 158 | 178 |

Note:

1, the weight of the equipment does not include abrasive body;

2. Please indicate the motor voltage and transmission layout when ordering (left-rotation or right-rotation: if there is no clear indication, the manufacturer will supply according to right-rotation).

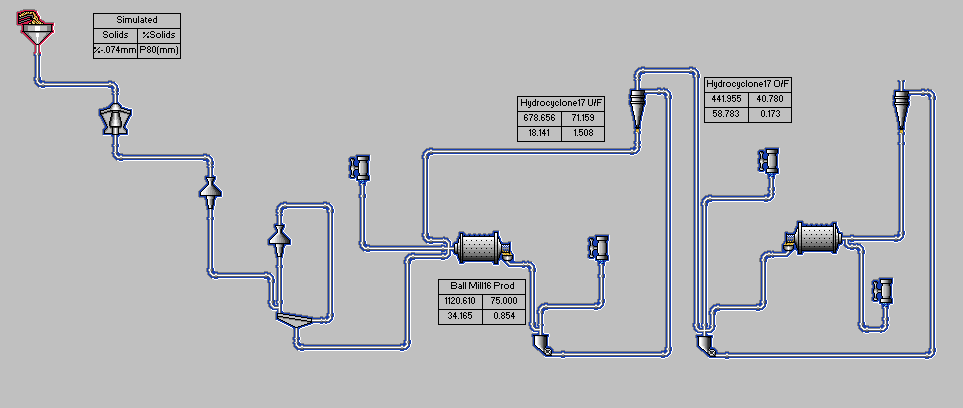

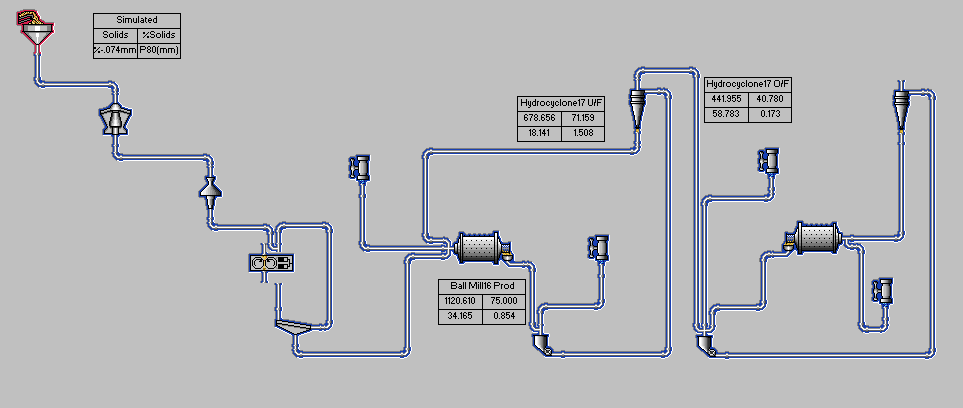

Mineral processing production line is composed of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, concentrator, dryer and other main equipment. The production line has the advantages of high efficiency, low energy consumption, large processing capacity and reasonable economy.

The production process of mineral processing line is: the mined ore is first broken by jaw crusher, broken to a reasonable fineness, by elevator and feeder evenly sent to the ball mill, ore crushing, grinding. The ball mill grinds the fine ore into the next step: classification. The spiral classifier cleans and classifies the ore mixture according to the principle of different specific gravity of solid particles and different precipitation rate in liquid. After a mineral mixture is washed and graded by a magnetic separator, the magnetic and mechanical forces are separated from the magnetic material in the mixture due to the different specific magnetization coefficients of various minerals. After the preliminary separation of magnetic separator, the mineral particles into the flotation machine, according to the different mineral properties of different drugs, so that the required minerals and other substances separated. After mineral separation, because it contains a lot of water, it must be concentrated by thickener and dried by dryer.