Device overview

The rotary kiln has the characteristics of simple structure, reliable operation and easy control of the production process. Through technological innovation, the rotary kiln calcination system equipment adopts domestic and foreign advanced hydraulic stopper device, metering plunger pump with high metering accuracy, high-precision speed regulating valve and contact graphite block sealing device and other domestic advanced equipment. technology. The kiln head can use industrial TV to watch the fire, the process flow simulates the fluorescent screen, and the calcination belt uses an infrared scanner to directly reflect the calcination status of the calcination belt on the computer. The use of these new technologies is intuitive, easy to operate, and reliable to use. The thermal system is stabilized and the equipment operation rate is improved. Compared with equipment of the same specification, the output is increased by 10%, and the heat consumption is reduced by 15%.

Uses of spodumene

Lithium carbonate is widely used in various fields including lithium-ion batteries, semiconductors, enamel glass, aluminum metal smelting, medicine, etc. Battery-grade lithium carbonate for lithium-ion battery manufacturing, industrial-grade and high-purity lithium carbonate for industrial production. Lithium hydroxide is widely used in the production of lithium salts and lithium-based greases, electrolytes for alkaline batteries, and absorption liquids for refrigerators, and in petroleum, chemical, light industry, and nuclear industries. Including two high-quality lithium hydroxide products, battery-grade single water and industrial-grade single water. Lithium chloride is mainly used in the field of air conditioning, used as flux, desiccant, chemical reagent, and used in fireworks, dry batteries and lithium metal. Provide high-quality industrial grade anhydrous lithium chloride products, mainly used in one-step electrolysis to produce battery-grade metal lithium raw materials, etc. Metal lithium and lithium-aluminum alloy are important materials for the production of various lithium-ion batteries. At the same time, metal lithium can also be used to prepare other lithium alloys, rubber, and pharmaceutical industries. Metal lithium and lithium-aluminum alloy products, including high-purity metal lithium, low-sodium metal lithium, and primary and secondary lithium-aluminum alloys. Mainly used in the production of various lithium batteries, light lithium aluminum alloys, synthetic rubber, pharmaceutical industry, etc. It is used in the production of nickel-metal hydride, nickel-cadmium battery electrolyte additives, lithium-ion battery cathode materials and as an important raw material for the production of other high-purity lithium-containing compounds.

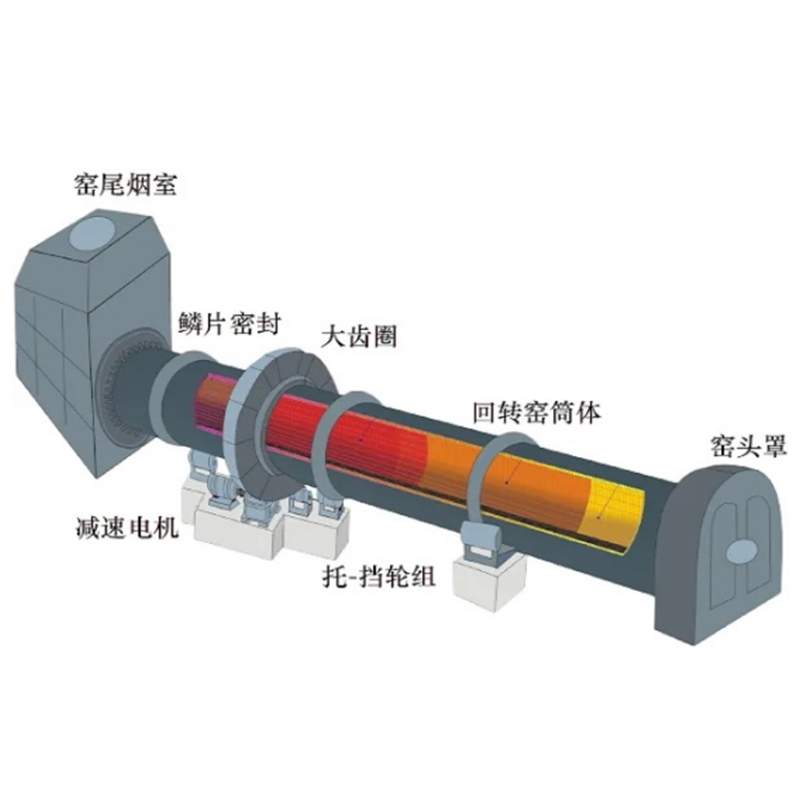

Equipment composition

The spodumene rotary kiln is composed of a cylinder body, a supporting device, a supporting device with a blocking wheel, a transmission device, a movable kiln head, a kiln tail sealing device, a combustion device and other components.

Spodumene rotary kiln process

The spodumene concentrate is manually sent from the concentrate silo to the bucket elevator to be lifted to the concentrate bin, and then added to the kiln tail of the lithium carbonate rotary kiln through the disc feeder and screw feeder, and the high temperature gas in the preheating section of the kiln tail is used. The concentrate is dried, and the concentrate is converted into β-type spodumene (tetragonal system , density 2400kg) by crystal transformation and roasting at a temperature of about 1200 ℃ in the calcination section . /m3 , namely baking material), the conversion rate is about 98% .

|

Specification |

Yield ( t/d ) |

Number of supports |

reducer |

electric motor |

Power (kW) |

|

Ø2.2 × 38m |

120 |

2 groups |

ZS125-5 |

YVF2-225M-4 |

45 |

|

Ø2.5 × 40m |

150 |

2 groups |

ZS145-5 |

YVF2-250M-4 |

55 |

|

Ø2.8 × 43m |

200 |

2 groups |

ZS165-6 |

YVF2-280S-4 |

75 |

|

Ø3.0 × 50m |

230 |

2 groups |

ZS165-3 |

YVF2-280M-4 |

90 |

|

Ø3.2 x 50m |

250 |

2 groups |

ZL130-16 |

YVF2-315L2-6 |

132 |

|

Ø3.6 x 55m |

400 |

2 groups |

ZSY560-63 |

YVF2-355M1-6 |

160 |

|

Ø3.8 × 58m |

500 |

2 groups |

ZSY560-63 |

YVF2-355M2-6 |

185 |

|

Ø4.0 × 60m |

600 |

2 groups |

ZSY630-35.5 |

YVF2-355M4-6 |

200 |

|

Ø4.3 × 6 2 m |

800 |

2 groups |

ZSY630-35.5 |

YVF2-355L3-6 |

250 |

Sichuan **Lithium Industry Co., Ltd. spodumene calcining rotary kilnΦ4.3×62m