Raw material mill is widely used in building materials, metallurgy, electric power and chemical industry grinding (drying and grinding) cement raw materials and other materials.

application

Iron ore, copper ore, gold ore, manganese ore, cobalt ore, lead zinc ore, bauxite, rare earth ore,

A. Ordinary raw material grinding is suitable for small and medium-sized raw material grinding system, generally used for grinding external separation ring flow grinding system.

B. Air sweep mill Air sweep mill is characterized by short and thick, large diameter of inlet and outlet hollow shaft, large gap between drying bin and grinding bin, no discharge grate plate at the end of grinding, so the ventilation resistance is very small, the wind speed of grinding bin can reach more than 5m/s, can enter a large number of hot air, so the drying ability is strong.

C. Tail unloading lifting cycle grinding The basic difference between tail unloading lifting cycle grinding and air sweeping grinding is that the incoming materials are discharged mechanically from the drying bin to the tail end of the grinding bin, and then sent to the classifier by the hoist, and the coarse materials are returned to the mill for cycle grinding

D. Mid-discharge lifting circular grinding Mid-discharge lifting circular grinding is the combination of air sweep grinding and tail discharge lifting circular grinding in terms of drying function; In terms of grinding effect, it is actually equivalent to two stage ring flow grinding system. The front end of the mill is provided with a drying bin, with good drying effect; The raw material is fed from the mill head, and the feed of the classifier is fed from the mill head and the mill tail into the coarse grinding bin and fine grinding bin respectively. The material is discharged in the mill and is carried to the powder separator by the elevator. Most of the material goes back to the fine grinding bin and the rest to the coarse grinding bin.

| 技术参数表 Technical Parameter Table | |||||||

| 规格 Spec./m (直径x长度) (Dia. x Length) | 磨机工 作转速 Speed(r/min) | 入料粒度 Feeding Size(mm) | 生产能力 Capacity(t/h) | 研磨体装载量 Griding Media Loading (t) | 主电动机 Main Motor (KW) | 主减速机 Main Reducer | 总重量Weight(t) |

| Φ2.2x7.0 | 21.7 | <25 | 20-25 | 35 | 380 | ZD70 | 62.5 |

| Φ2.2x7.5 | 21.7 | <25 | 22-26 | 35 | 380 | ZD70 | 64 |

| Φ2.2x8.0 | 21.5 | <25 | 23-27 | 36 | 475 | ZD70 | 66 |

| Φ2.2x9.0 | 21.5 | <25 | 24-28 | 40 | 475 | ZD70 | 69 |

| Φ2.4x7.0 | 21.5 | <25 | 24-28 | 36.5 | 475 | ZD70 | 81 |

| Φ2.4x8.0 | 21.5 | <25 | 26 〜30 | 42 | 570 | ZD80 | 86 |

| Φ2.4x9.0 | 21.5 | <25 | 28 〜32 | 47 | 570 | ZD80 | 92 |

| Φ 2.4x 10 | 20.3 | <25 | 30 〜35 | 52 | 630 | ZD80 | 108 |

| Φ2.6x8.0 | 19.7 | <25 | 30 〜35 | 51 | 630 | MBY630 | 112 |

| JDX630 | |||||||

| Φ2.6x9.0 | 19.7 | <20 | 40-45 | 58 | 710 | MBY630 | 120 |

| JDX630 | |||||||

| Φ2.6x10 | 19.7 | <20 | 45 〜50 | 64 | 800 | MBY710 | 130 |

| JDX710 | |||||||

| Φ3.0x9.0 | 18.2 | <20 | 50 〜55 | 78 | 1000 | MBY800 | 158 |

| JDX800 | |||||||

| Φ3.0x11 | 18.2 | <20 | 55-60 | 95 | 1250 | MBY800 | 178 |

| JDX800 | |||||||

| Φ3.2x10 | 17.8 | <25 | 60-65 | 100 | 1400 | MBY900 | 200 |

| JDX900 | |||||||

| Φ3.2x 11 | 17.8 | <25 | 70 〜80 | 110 | 1400 | MBY900 | 215 |

| JDX900 | |||||||

| Φ3.4x7.5 | 16.9 | <20 | 50-55 | 80 | 1000 | MBY800 | 178 |

| Φ3.4x7.5+1.8 | 16.9 | <20 | 55-60 | 70 | 1250 | MBY800 | 190 |

| Φ3.5x10 | 16.8 | <20 | 70-75 | 80 | 1250 | JS110-A | 200 |

| MFY125 | |||||||

| Φ3.8x7.5 | 16.5 | <15 | 85-90 | 95 | 1400 | MFY140 | 185 |

| Φ3.8x8.5 | 16.5 | <15 | 90 〜95 | 108 | 1400 | MFY140 | 195 |

| Φ4.6 x 8.5+3.5 | 15 | <15 | 140-150 | 150 | 2800 | MFY280 | 325 |

| JS140-A | |||||||

| Φ4.6x9.5+3.5 | 15.1 | <15 | 180-190 | 180 | 3550 | JS150-B | 345 |

| Φ4.6x10+3.5 | 15.1 | <15 | 200-210 | 190 | 3550 | JS150-B |

370 |

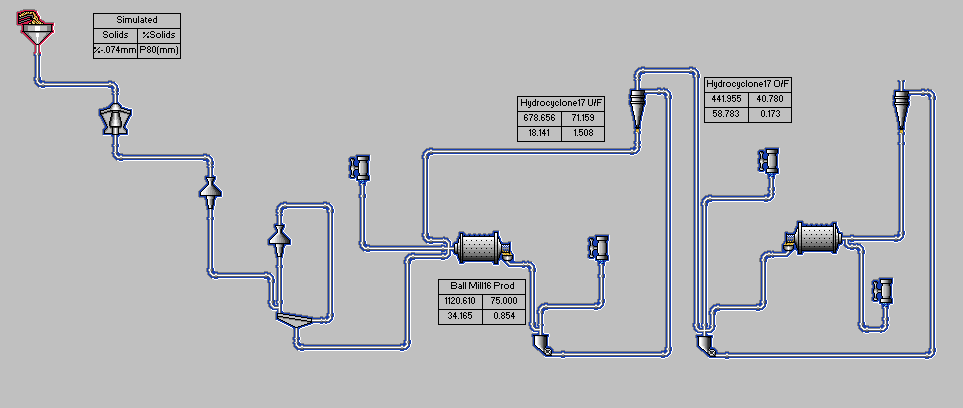

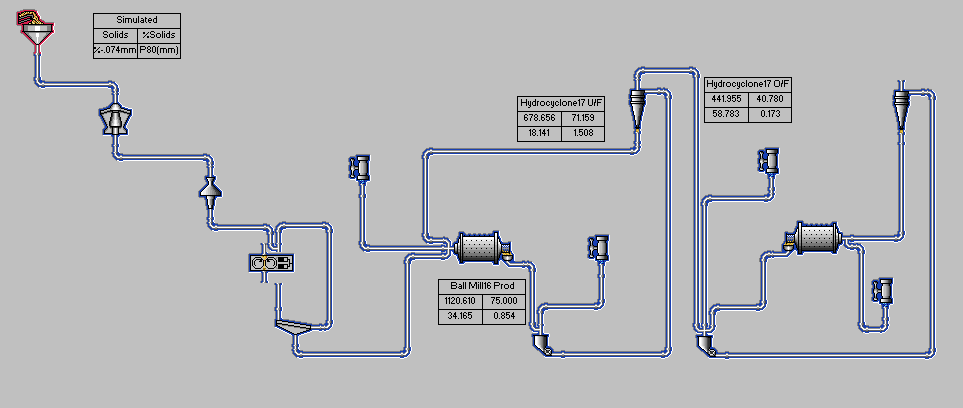

Mineral processing production line is composed of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, concentrator, dryer and other main equipment. The production line has the advantages of high efficiency, low energy consumption, large processing capacity and reasonable economy.

The production process of mineral processing line is: the mined ore is first broken by jaw crusher, broken to a reasonable fineness, by elevator and feeder evenly sent to the ball mill, ore crushing, grinding. The ball mill grinds the fine ore into the next step: classification. The spiral classifier cleans and classifies the ore mixture according to the principle of different specific gravity of solid particles and different precipitation rate in liquid. After a mineral mixture is washed and graded by a magnetic separator, the magnetic and mechanical forces are separated from the magnetic material in the mixture due to the different specific magnetization coefficients of various minerals. After the preliminary separation of magnetic separator, the mineral particles into the flotation machine, according to the different mineral properties of different drugs, so that the required minerals and other substances separated. After mineral separation, because it contains a lot of water, it must be concentrated by thickener and dried by dryer.