Horomill

Product Introduction

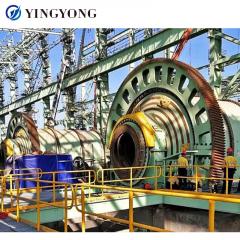

Horomill is based on the principle of bed crushing, ingeniously combines the major advantages of ball mill and roller press, using the medium of extrusion under the roller surface linear velocity of medium, a feeding of material in the equipment to achieve multiple squeeze grinding, avoid the process problems of the vertical mill and roller press, found a vertical mill and rolling machine can give full play to the new way of energy saving potential. It is suitable for grinding cement clinker, slag, fly ash, limestone and other materials.

Horomill is based on the principle of bed crushing, ingeniously combines the major advantages of ball mill and roller press, using the medium of extrusion under the roller surface linear velocity of medium, a feeding of material in the equipment to achieve multiple squeeze grinding, avoid the process problems of the vertical mill and roller press, found a vertical mill and rolling machine can give full play to the new way of energy saving potential. It is suitable for grinding cement clinker, slag, fly ash, limestone and other materials.

Working principle

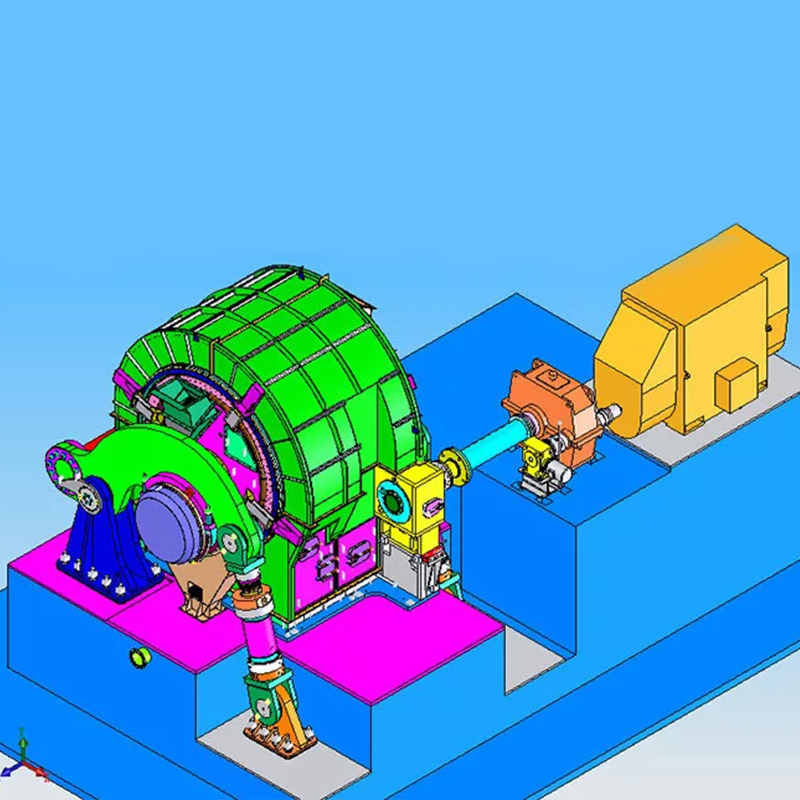

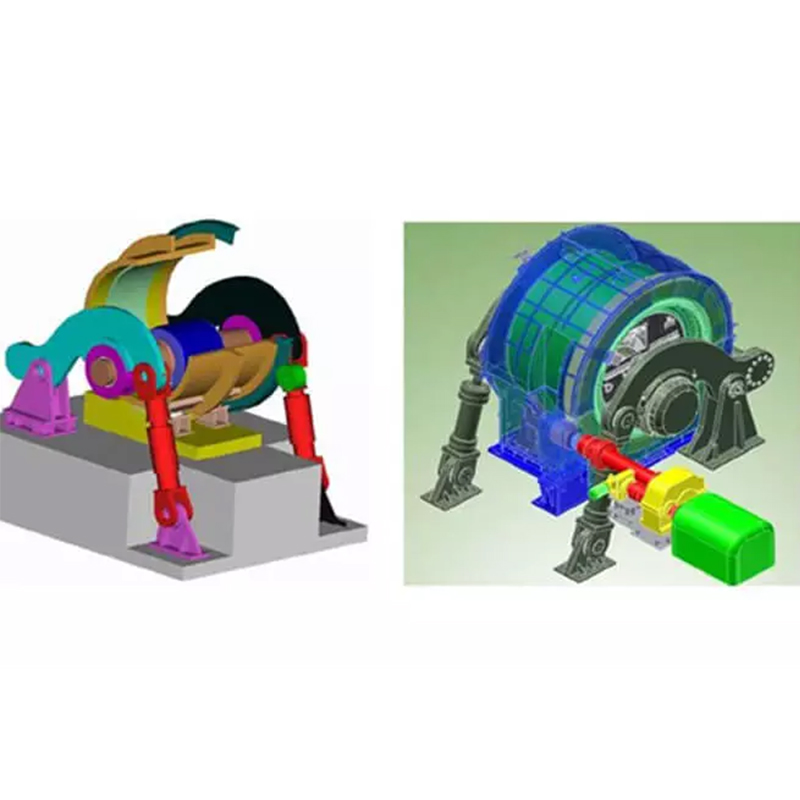

Horomill consists of driving device, frame, oil film bearing, rotary cylinder, pressure device, material movement control and propulsion device and sealing shell. The rotary cylinder body is supported on the dynamic hydraulic oil film bearing, which is driven by the transmission device. The pressure roller is suspended in the rotary cylinder body. Wear resistant lining plate is set inside the rotary cylinder. Grinding pressure required by pulverized materials is transmitted to the pressure roller by the hydraulic cylinder through the pressure device, which directly transmits grinding pressure to the pulverized materials.

Horomill consists of driving device, frame, oil film bearing, rotary cylinder, pressure device, material movement control and propulsion device and sealing shell. The rotary cylinder body is supported on the dynamic hydraulic oil film bearing, which is driven by the transmission device. The pressure roller is suspended in the rotary cylinder body. Wear resistant lining plate is set inside the rotary cylinder. Grinding pressure required by pulverized materials is transmitted to the pressure roller by the hydraulic cylinder through the pressure device, which directly transmits grinding pressure to the pulverized materials.

Into the grinding material had an centrifugal effect under the action of centrifugal force and pressure are attached to the grinding zone when the substances move material to the upper cylinder is installed under the scraper device inside the mill, scraping on the material being thrown on material propeller of propeller by material according to the set speed will be material by the entry point to the outlet according to similar spiral trajectory movement. During the movement of the material from the entrance to the exit, due to the function of the material bed, the material is repeatedly crushed, pressed, split, folded, and rolled. At the exit side, when the spiral movement material is scraped off by the scraping plate, it will be picked up by the discharge hopper and discharged from the mill to the next process, which is the third stage of centrifugation. In order to meet the technological requirements or to set the change of output, the speed of material propulsion can be adjusted by adjusting the position of material propeller, so as to adjust the amount of material passing through the mill.

The process flow above is the micro powder process of steel and iron slag, which belongs to online drying. The process is simple and the process is smooth.

Less equipment, clear route, divided into two major parts: one is the material circulation loop; All the way through is the gas loop. Material circulation loop consists of horizontal roller mill + elevator + drying equipment + lock air valve + grinding belt conveyor. The gas circulation loop is composed of "drying + grading" equipment + dust collector + circulating fan. After grinding, materials are mechanically lifted from the elevator to the separator. The grading equipment has the characteristics of upper multi-point feeding, lower air inlet and counter-current sorting. The powder selecting blade is designed into a streamline shape that can be adjusted online, so the grain size curve of finished products can be continuously adjusted, which is flexible and convenient.

Less equipment, clear route, divided into two major parts: one is the material circulation loop; All the way through is the gas loop. Material circulation loop consists of horizontal roller mill + elevator + drying equipment + lock air valve + grinding belt conveyor. The gas circulation loop is composed of "drying + grading" equipment + dust collector + circulating fan. After grinding, materials are mechanically lifted from the elevator to the separator. The grading equipment has the characteristics of upper multi-point feeding, lower air inlet and counter-current sorting. The powder selecting blade is designed into a streamline shape that can be adjusted online, so the grain size curve of finished products can be continuously adjusted, which is flexible and convenient.

Feedback from contact with us

Related Product

SAG Mill

Product description

The SAG mill also kown as medium-free grinding mill. The ore from the st...

Learn More>

Overflow ball Mill

Product description

The wet ball mill for mining is divided into lattice ball mill and overf...

Learn More>

Overflow ball Mill

Product description

A rod mill is a mill in which the grinding body is a steel rod. The rod ...

Learn More>