With the increasing maturity and promotion of the comprehensive utilization technology of fly ash in China, the comprehensive utilization of fly ash is not limited to the requirements of environmental protection, and the huge economic benefits of the comprehensive utilization of fly ash have been reflected. In some developed areas of our country, the demand for fine ash of fly ash products even exceeds supply. Now a large number of domestic coal-fired power plant emissions of the original ash, the fineness of the general change between 20-50% (45um square hole screen margin), not up to the national standards of level I ash (45um square hole screen margin is not more than 12%), II ash (45Pm square hole screen margin is not more than 20%) requirements.

Using the special ultrafine mill for fly ash to grind the raw ash or the coarse ash after sorting to achieve the purpose of full utilization of fly ash and create greater economic benefits.

The fly ash mill produced by our company has the following characteristics:

A. Ensure that the fineness of the ground ash can meet the standards of GRADE H ash;

B. The glass beads in the ash are kept in their original state after ultra-fine grinding.

C. The output and quality of ground ash are stable and reliable.

D. The specially designed middle compartment device is convenient to control the material surface and flow rate of the material in front of the warehouse, so that the screening curve in the mill tends to be reasonable.

E. The middle stopper ring in the back bin is designed with activation function to avoid the retention area produced by micro-steel forging and improve the grinding efficiency.

| 规格 Spec./m (直径x长度) (Dia.x Length) | 磨机工 作转速 Speed(r/min) | 生产能力 Capacity(t/h) | 硏磨体装载量 Griding Media Loading (t) | 主电动机 Main Motor (KW) | 主减速机 Main Reducer | 总重量Weight(t) | |

| 易磨 Easy Grinding | 难磨 Hard Grinding | ||||||

| Φ1.83x7.0 | 23.8 | 12-13 | 5-6 | 22 | 245 | ZD60 | 43.5 |

| Φ1.83x8.0 | 23.8 | 15-16 | 7-8 | 26 | 280 | ZD60 | 46 |

| Φ1.83x9.5 | 24.1 | 16-17 | 11-12 | 31 | 355 | ZD70 | 56 |

| Φ2.1 x8.5 | 23.9 | 18-19 | 14-15 | 36 | 475 | ZD70 | 66 |

| Φ2.1 x10 | 23.9 | 19-20 | 15-16 | 42 | 475 | ZD70 | 70 |

| Φ2.2x9.0 | 21.5 | 19-20 | 15-16 | 40 | 475 | ZD70 | 69 |

| Φ2.2x9.5 | 21.5 | 21-22 | 17-18 | 41 | 475 | ZD70 | 74 |

| Φ2.2x11 | 21.5 | 23-24 | 18-19 | 50 | 570 | ZD80 | 109 |

| Φ2.2x 13 | 21.5 | 25-26 | 20-21 | 58 | 630 | ZD80 | 114 |

| Φ 2.4x12 | 20.3 | 29-30 | 22-23 | 63 | 800 | MBY630 | 128 |

| MBY710 | |||||||

| Φ2.4x13 | 20.3 | 32-33 | 25-26 | 68 | 800 | MBY630 | 138 |

| MBY710 | |||||||

| Φ2.6x13 | 19.7 | 37-38 | 30-31 | 82 | 1000 | MBY800 | 158 |

| Φ3.2x 13 | 17.8 | 55-60 | 43-48 | 128 | 1600 | MBY900 | 230 |

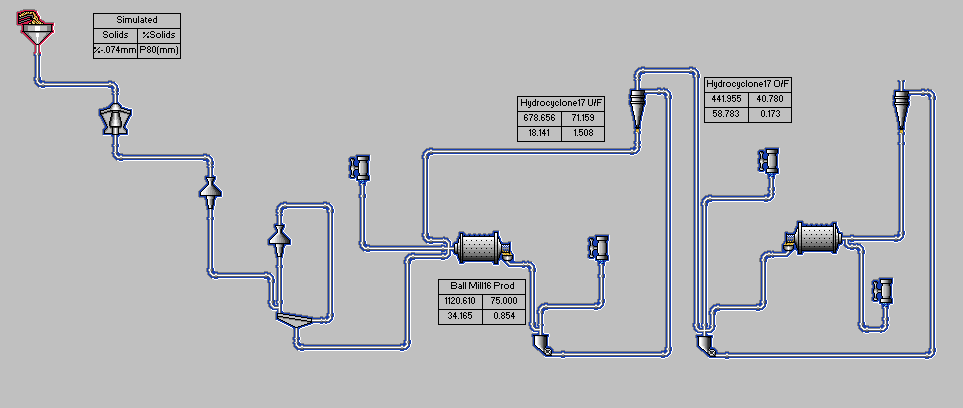

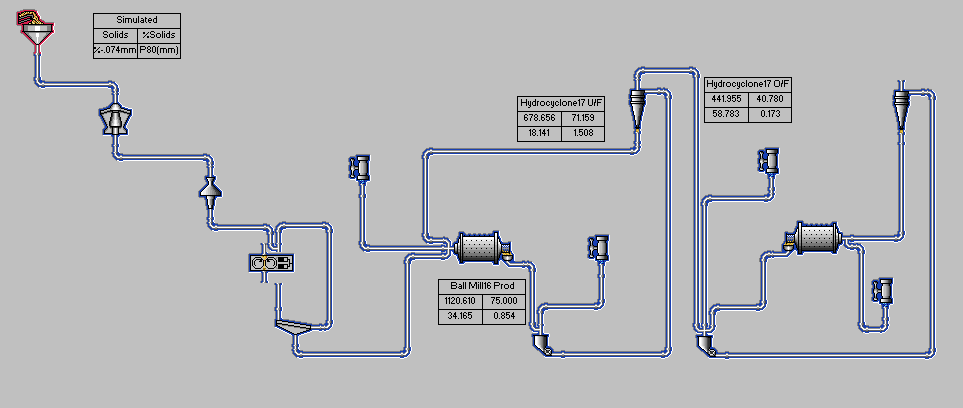

Mineral processing production line is composed of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, concentrator, dryer and other main equipment. The production line has the advantages of high efficiency, low energy consumption, large processing capacity and reasonable economy.

The production process of mineral processing line is: the mined ore is first broken by jaw crusher, broken to a reasonable fineness, by elevator and feeder evenly sent to the ball mill, ore crushing, grinding. The ball mill grinds the fine ore into the next step: classification. The spiral classifier cleans and classifies the ore mixture according to the principle of different specific gravity of solid particles and different precipitation rate in liquid. After a mineral mixture is washed and graded by a magnetic separator, the magnetic and mechanical forces are separated from the magnetic material in the mixture due to the different specific magnetization coefficients of various minerals. After the preliminary separation of magnetic separator, the mineral particles into the flotation machine, according to the different mineral properties of different drugs, so that the required minerals and other substances separated. After mineral separation, because it contains a lot of water, it must be concentrated by thickener and dried by dryer.