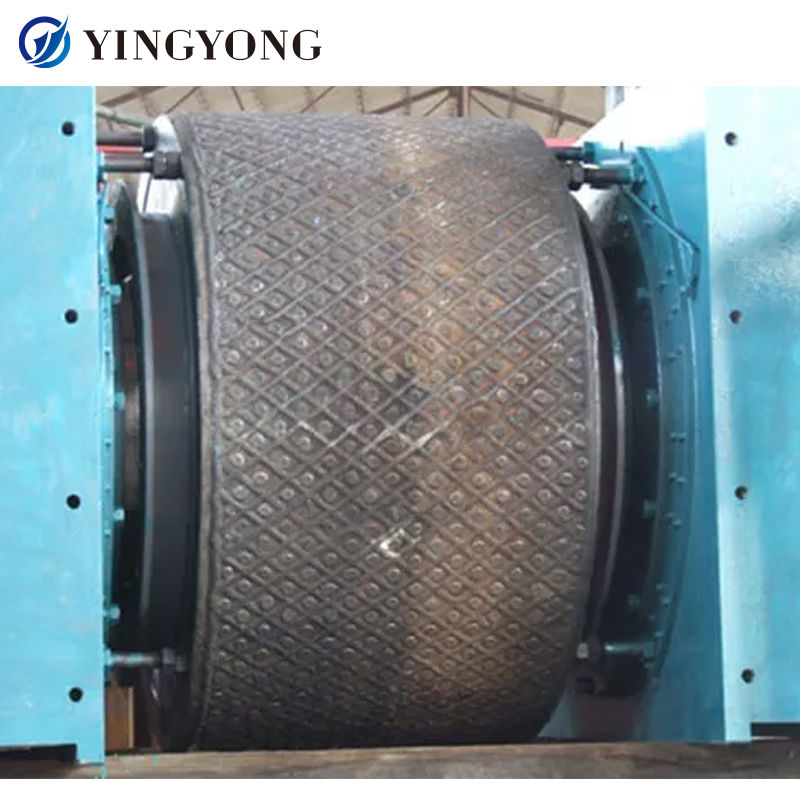

Also called extrusion mill roller press, roller mill, is a new kind of energy-saving cement grinding equipment, replace the high energy consumption, low efficiency of ball mill grinding system, and reduce the steel consumption and noise function, apply to the new plant construction, also can be used in old factory technical renovation, make the ball mill system yields by 30-50%, after extrusion, the material feeding bread in 0.08 mm thin material accounts for 20-35%, accounted for 65-85% less than 2 mm, the internal structure of small particles, filled with many tiny crack because of extrusion, and greatly improve ease of grinding. The roll surface is hot surfacing, and the maintenance of wear resistant layer is more convenient.

Roller press is designed according to the principle of material bed grinding, its main characteristics are: high pressure, full speed, full material, material bed crushing. The roller press consists of two extruding rollers which rotate synchronously in the opposite direction, one is the fixed roller and the other is the movable roller.

The material is fed from the top of the two rollers, which is continuously carried between the rollers by the extrusion roller. Under the high pressure of 100-150mpa, the compacted cake is discharged from the bottom of the machine. The discharged cake contains a certain proportion of fine finished products. In the interior of non-finished particles, a large number of cracks were generated, which improved the material's wearability, and greatly reduced the energy consumption of grinding in the further crushing process.

The material through grinding roller is mainly divided into three stages: full material density, lamination and crushing, agglomerating and discharging stage.

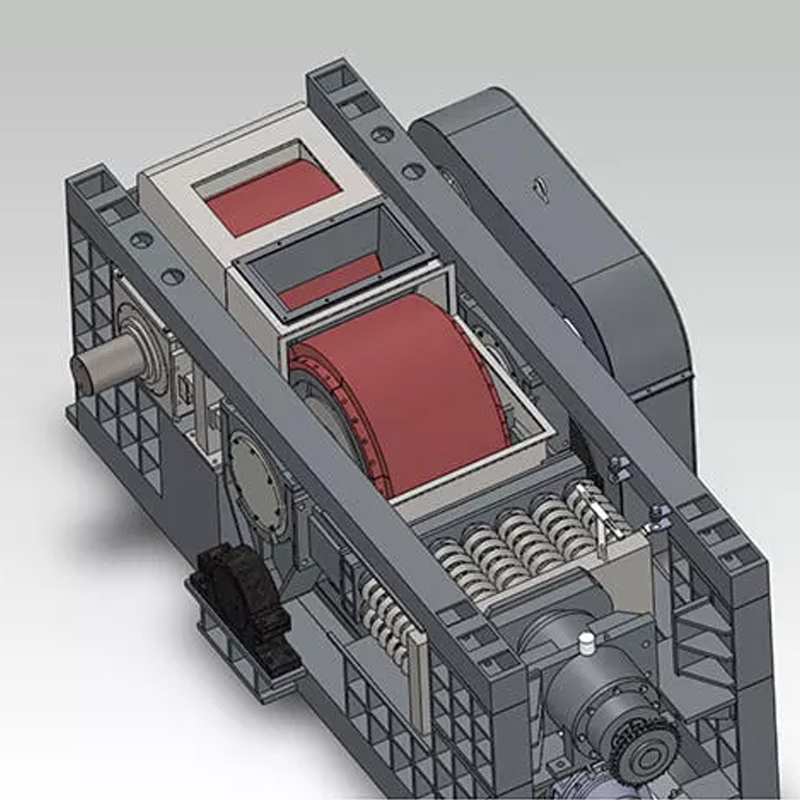

Roller press consists of frame, two roller system, transmission device, torque support, roller cover, feeding device, hydraulic (pressurization) system, main bearing lubrication system, dry oil lubrication system, electrical system and other parts.

(1) increasing production: in grinding roller machine installed in the system, the high voltage load by double roller diameter is passed to the grinding material layer, the interaction between the most energy is used in the material extrusion, sound energy and heat energy produced by the friction material can be converted into material deformation, the deformation, tearing, crushing, can give full play to the potential power to make the grinding equipment, increase production of up to 50-100%, the total energy consumption can be reduced by 20% - 30%, improved the production efficiency of the whole system.

(2) reduce power consumption: grind materials with roller press. Not only the particle size of the material is greatly reduced, but the bond function index is also significantly reduced, which greatly improves the grinding condition of the subsequent mill and significantly reduces the unit power consumption of the whole grinding system. The total power consumption of the grinding system can be significantly reduced. Compared with the traditional grinding method, the energy saving is 25-50%, and the annual electricity saving benefit is considerable.

(3) saving investment: compared with tube mill, roller mill with the same production capacity is simple in structure, small in size, light in weight and small in space, which can save civil construction investment and facilitate the transformation of the original grinding system. In addition, the operation and maintenance of roller press is also very simple.

(4) good working environment: the material is continuously and stably crushed in the extrusion roller cover, and the harmful dust is not easy to be diffused. At the same time, because there is almost no impact, the noise of the roller is much lower than that of the tube mill.

(5) easy to develop: the traditional tube mill is restricted by processing, transportation, heat treatment and other conditions, and the upsizing of tube mill is greatly restricted. The grinding system of matching roller press solves the problem well. So that the grinding system to large - scale development into a reality.

|

Model |

Capacity(t/h) |

Motor (kW) |

Linear velocity(m/s) |

|

100-60 |

105~150 |

2×(315) |

1.36 |

|

120-45 |

100~140 |

2×220 |

1.38 |

|

120-80 |

240~300 |

2×450 |

1.31 |

|

140-80 |

340~400 |

2×560 |

1.47 |

|

140-100 |

400~480 |

2×630 |

1.48 |

|

140-110 |

500~600 |

2×710 |

1.6 |

|

140-140 |

550~630 |

2×800 |

1.48 |

|

180-170 |

900~1000 |

2×1400 |

1.7 |