Air sweep coal mill is the main equipment for cement clinker production of rotary kiln, and also suitable for thermal power generation, metallurgical industry, chemical industry, sugar industry and other pulverizing equipment system.

application

Iron ore, copper ore, gold ore, manganese ore, cobalt ore, lead zinc ore, bauxite, rare earth ore,

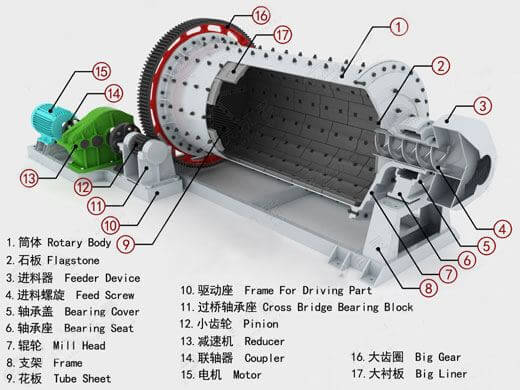

The product principle

Its main component is a large diameter, small length of the cylinder, through the transmission mechanism can be rotated. The material enters the barrel through the feed port and is thoroughly crushed, because the falling process of iron ball and ore produces huge falling impact and self-grinding. The continuous feeding of the ore produces considerable pressure, causing the ore to move from the feed port to the discharge port. Finally, the acceptable particles are discharged through the discharge outlet. Acceptable ore particles are removed by water by wet grinding or by air by dry grinding. Discharge mouth is equipped with discharge grate, discharge mouth pulp layer is low. These two factors prevent the ore from being over-ground and the iron ball from being discarded. Under the same circumstances, the processing capacity of the energy-saving grate mill is larger. Rolling bearings have made great contributions to energy saving.

Product structure

Product features

A. can be continuous production, production capacity.

B. Fineness is easy to adjust.

C. compact structure, smooth operation, convenient installation and maintenance, long service life.

D. strong adaptability to materials, can grind various hardness of coal.

| 项目Item/规格Spec. (m) | Φ1.7x2.5 | Φ2.2x3.0 | Φ2.2x3.5 | Φ2.2x4.4 | Φ2.2x4.4+1.3 | Φ2.4x4.75 | Φ2.4x4.5+2 | Φ2.5x3.9 | |

| 工作转速Speed (r/min) | 25.4 | 21.3 | 21.3 | 22.4 | 22.4 | 20.4 | 20.4 | 20 | |

| 生产能力 Capacity (t/h) | 3~5 | 5~6 | 6~7 | 8~9 | 8~9 | 12~14 | 11~12 | 10 | |

| 产品细度 Fineness R80(%) | 10~12 | 10~12 | 10~12 | 10~12 | 10~12 | 8~10 | 8~10 | 8~10 | |

| 进料粒度Feeding Size (mm) | <25 | <25 | <25 | <25 | <25 | <25 | <25 | <25 | |

| 研磨体装载量Grinding Media Loading (t) | 7.5 | 13 | 15 | 20 | 20 | 22 | 22.5 | 22 | |

| 水分 Mositure (%) | 进磨Inlet | <10 | <10 | <10 | <10 | <10 | <10 | <10 | <10 |

| 岀磨Outlet | <2 | <2 | <2 | <2 | <2 | <2 | <2 | <2 | |

| 温度 Temp.(℃) | 进磨Inlet | <350 | <350 | <350 | <350 | <350 | <350 | <350 | <350 |

| 出磨Outlet | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 70~90 | |

| 主减速机Main Reducer | ZD45 | ZD60 | ZD60 | ZD60 | ZD60 | ZD60 | ZD60 | ZD60 MBY450 | |

| 主电动机Main Motor (KW) | 95 | 180 | 210 | 250 | 250 | 280 | 315 | 315 | |

| 总重量Weight (t) | 23 | 38 | 41 | 46 | 48.5 | 54 | 76 | 62 | |

| 项目Item/规格Spec. (m) | Φ2.6x5.25+2.25 | Φ2.8x5+3 | Φ2.9x4.1 | Φ3.0x6+3 | Φ3.2x6.75+2 | Φ3.4x6+3 | Φ3.8 x7+2.5 | Φ3.8x7.25+3.5 | |

| 工作转速Speed (r/min) | 19.7 | 18.3 | 18.8 | 17.3 | 16.9 | 17.5 | 16.4 | 16.4 | |

| 生产能力 Capacity (t/h) | 13~14 | 16~17 | 14~16 | 19~20 | 27~29 | 28~30 | 38~40 | 41~43 | |

| 产品细度 Fineness R80(%) | 8~10 | 8~10 | 8~10 | 8~10 | 8~10 | 12 | 12 | 12 | |

| 进料粒度Feeding Size (mm) | <25 | <25 | <25 | <25 | <25 | <25 | <25 | <25 | |

| 研磨体装载量Grinding Media Loading (t) | 28 | 32 | 35 | 43 | 50 | 55 | 80 | 85 | |

| 水分 Mositure (%) | 进磨Inlet | <10 | <12 | <10 | <10 | <10 | <12 | <12 | <12 |

| 岀磨Outlet | <2 | <2 | <2 | <2 | <2 | <2 | <2 | <2 | |

| 温度 Temp.(°C) | 进磨Inlet | <350 | <350 | <350 | <350 | <350 | <350 | <350 | <350 |

| 出磨Outlet | 70~90 | 60~80 | 60~80 | 70~90 | 80~90 | 60~80 | 60~80 | 60~80 | |

| 主减速机Main Reducer | ZD70 MBY450 | ZD70 MBY500 | ZD80 MBY560 | ZD80 MBY560 | JDX630 | JDX710 | MBY710 | MBY800 | |

| 主电动机Main Motor (KW) | 400 | 500 | 500 | 630 | 710 | 800 | 1250 | 1400 | |

| 总重量Weight (t) | 98 | 107 | 78 | 124 | 148 | 162 | 178 | 220 | |

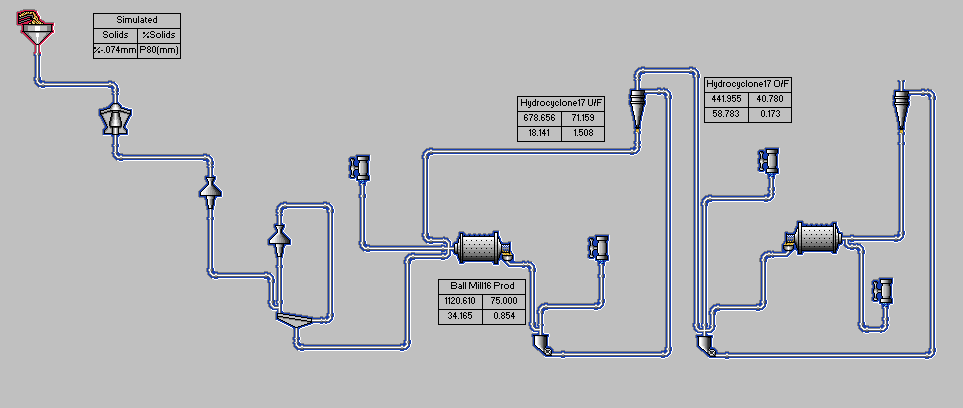

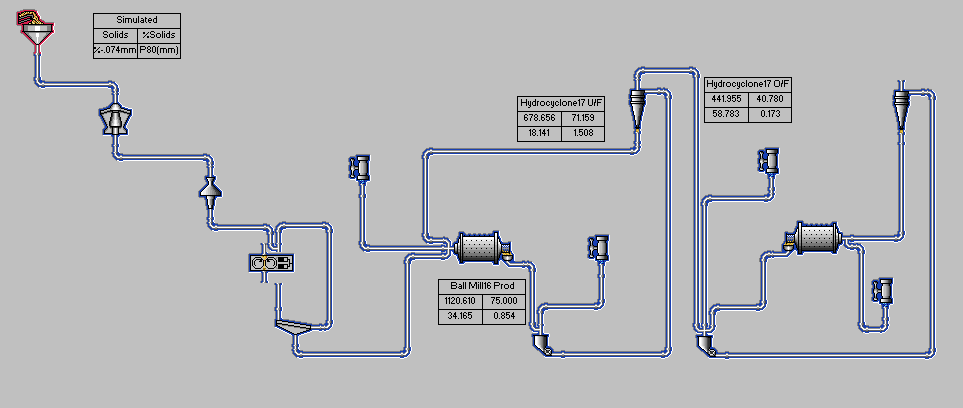

Mineral processing production line is composed of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, concentrator, dryer and other main equipment. The production line has the advantages of high efficiency, low energy consumption, large processing capacity and reasonable economy.

The production process of mineral processing line is: the mined ore is first broken by jaw crusher, broken to a reasonable fineness, by elevator and feeder evenly sent to the ball mill, ore crushing, grinding. The ball mill grinds the fine ore into the next step: classification. The spiral classifier cleans and classifies the ore mixture according to the principle of different specific gravity of solid particles and different precipitation rate in liquid. After a mineral mixture is washed and graded by a magnetic separator, the magnetic and mechanical forces are separated from the magnetic material in the mixture due to the different specific magnetization coefficients of various minerals. After the preliminary separation of magnetic separator, the mineral particles into the flotation machine, according to the different mineral properties of different drugs, so that the required minerals and other substances separated. After mineral separation, because it contains a lot of water, it must be concentrated by thickener and dried by dryer.