Equipment use

Externally heated electric rotary kiln is suitable for combustion, roasting, decomposition and drying of non-metallic ores, metal ores, medicine, food, chemical products and agricultural products. Such as: lithium iron phosphate, battery recycling materials, coal-based (washed) kaolin, basic magnesium carbonate, magnesium hydroxide, magnesium chloride, molecular sieve (particle, powder) catalyst, copper sulfate, barite, nickel oxide, titanium dioxide, zinc mines, sewage sediments, agricultural wastes and industrial wastes, etc.

Equipment Overview

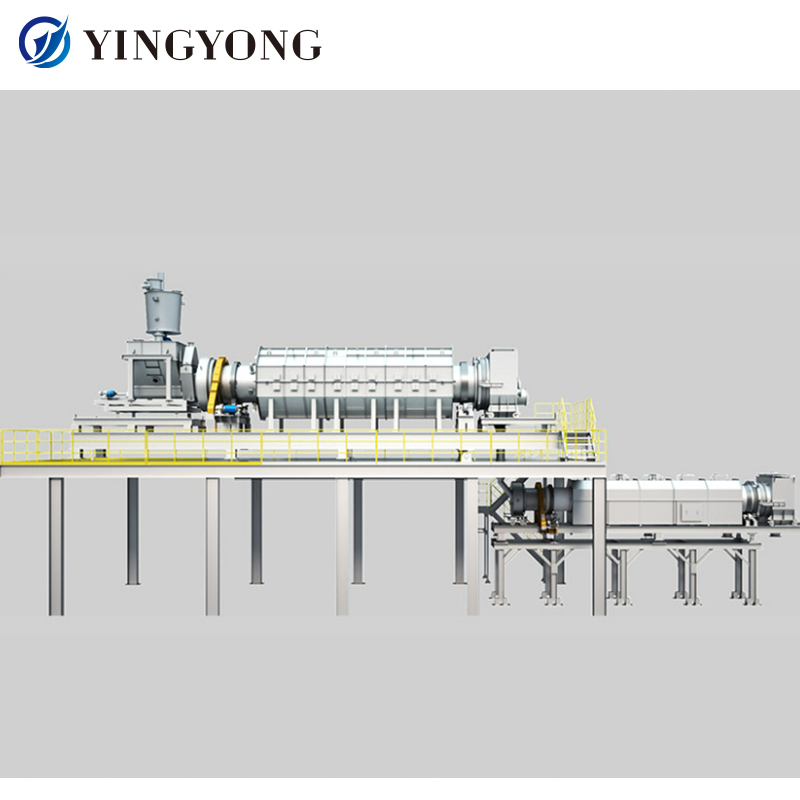

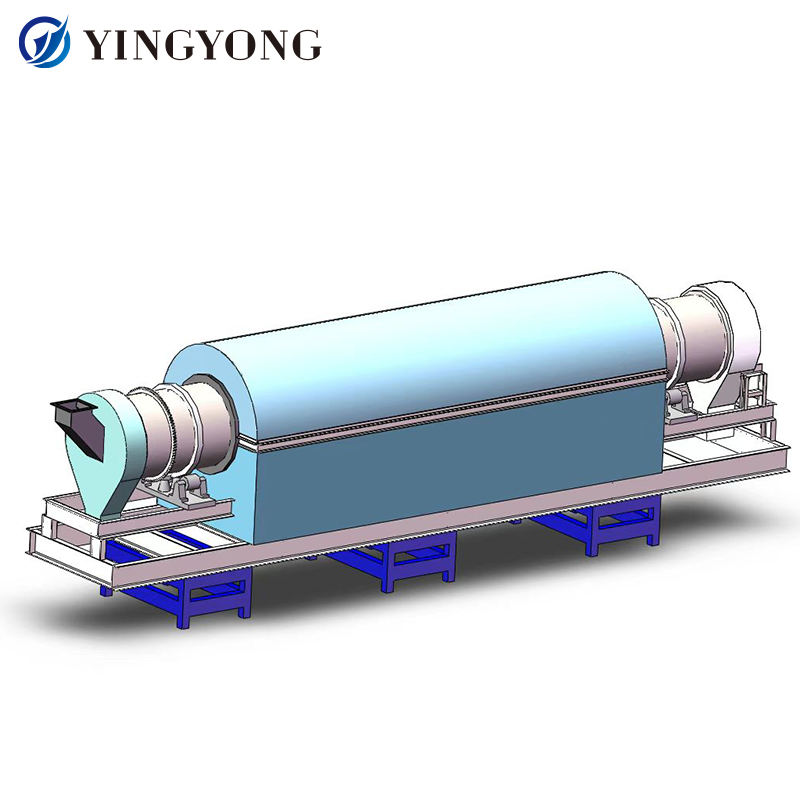

The externally heated electric rotary kiln is a new type of rotary kiln derived from the original single-cylinder rotary kiln and combined with customer production needs and environmental protection requirements, which can use electricity as a heat source for heating; It is a new type of practical environmental protection rotary kiln equipment developed by our company.

Equipment composition

The external heating electric rotary kiln is mainly composed of six parts: combustion system, control system, heating cavity cylinder, kiln body, driving device, feeding and discharging system. All components are mounted on a monolithic frame made of steel structure.

1. The combustion system is mainly composed of burner nozzle, proportional control valve, solenoid valve, electric actuator, atomization combustion-supporting device, ignition device, etc.

2. The cylinder body is equipped with a sprocket or gear, and both ends are supported by rollers, which are driven by a frequency-modulating motor through the sprocket or gear. The cylinder material can be selected from different materials according to the process requirements. Built-in copy board.

3. The kiln body is located on the steel frame, which is mainly made of lightweight thermal insulation materials. Adopt folding block, zirconium-containing ceramic cotton blanket to reduce heat storage. The labyrinth seal is composed of the refractory material and the fire retaining ring of the cylinder.

4. The drive device can use chain drive and gear drive. The reducer has two output shafts, and a manual device can be added to shake the cylinder to protect it from damage in an emergency.

5. The feeding and unloading system is mainly composed of feeding hopper, feeding screw, stirring device, feeding cover, etc.

6. The electric heating device adjusts the power of the electric heating device according to the temperature displayed by the thermocouple and the drying condition of the finished product, thereby changing the drying effect.

Equipment process

The material to be burned is uniformly fed into the kiln barrel from the kiln head hopper through the feeding mechanism. Driven by the transmission device, the material moves forward along the axis of the barrel with the rotation of the barrel, and the copy plate turns the material over to make it calcined evenly. . A heating chamber is arranged on the outside of the cylinder. The heat generated by calcination is transferred to the material through the cylinder, and the material is decomposed, dried, calcined and roasted at high temperature. The calcined material is discharged through the unloading valve and used after cooling and packaging.

Equipment Features

1. The equipment has a certain airtight function, so that the atmosphere in the furnace can be controlled within a certain range, and the flue gas, dust or water vapor will not be scattered into the workshop;

2. All refractory and thermal insulation materials are made of aluminum silicate casting fiber vacuum casting modules and light aluminum silicate fiber blankets, which have high thermal efficiency, light weight, thinness, energy saving, and simple construction, making the kiln power much smaller than other similar types. products, greatly reducing production costs;

3. The use of TISCO 310S stainless steel as the kiln body rotary furnace tube and contact with the material greatly reduces the degree of magnetic pollution to the material, and the furnace tube does not fall off or deteriorate;

4. The material travels in a spiral line in the constant temperature zone at 600-650°C, which avoids the problem that the material is in series before and after the general converter, and the time is too long or too short. .

5. Tailor-made and fully humanized design, the equipment exterior is sprayed with plastic, and the safety protection cover is set up in line with the modeling design, with humanized instruction labels and warning instructions, so that the entire processing and manufacturing accuracy and appearance of the equipment can reach or exceed the imported ones. equipment level.

|

No. |

Model |

Operating temperature |

Rotary kiln size |

Heater power |

Inclination |

production capability |

power supply |

weight |

|

1 |

YDH100 |

1100℃ |

φ0.1×4.5m |

36kW |

0.5~5.0° |

~4kg/h |

380VAC 50HZ |

~4T |

|

2 |

YDH150 |

Φ0.15×4.5m |

42kW |

~8kg/h |

~4T |

|||

|

3 |

YDH200 |

φ0.2×4.5m |

48kW |

~15kg/h |

~4T |

|||

|

4 |

YDH350 |

φ0.35×9m |

68kW |

0.5~4.0° |

~120kg/h |

~8T |

||

|

5 |

YDH400 |

φ0.4×9m |

108kW |

~150kg/h |

~10T |

|||

|

6 |

YDH500 |

φ0.5×9m |

180kW |

~250kg/h |

~12T |

|||

|

7 |

YDH620 |

φ0.62×10.5m |

260kW |

0.5~3.0° |

~300kg/h |

~15T |

||

|

8 |

YDH700 |

φ0.7×10.5m |

280kW |

~360kg/h |

~18T |

|||

|

9 |

YDH800 |

φ0.8×10.5m |

350kW |

~480kg/h |

~20T |

|||

|

10 |

YDH940 |

φ0.94×12m |

400kW |

0.5~2.5° |

~650kg/h |

~25T |

||

|

11 |

YDH1000 |

φ1.0×12m |

410kW |

~750kg/h |

~28T |

|||

|

12 |

YDH1100 |

φ1.1×12m |

460kW |

~900kg/h |

~30T |

|||

|

13 |

YDH1250 |

φ1.25×12m |

500kW |

~1000kg/h |

~35T |

|||

|

14 |

YDH1420 |

φ1.42×13.5m |

600kW |

~1350kg/h |

~40T |

|||

|

15 |

YDH1500 |

φ1.5×13.5m |

750kW |

~1500kg/h |

~45T |

|||

|

16 |

YDH1600 |

φ1.6×15m |

900kW |

~1600kg/h |

~50T |

|||

|

17 |

YDH1800 |

φ1.8×15m |

1000kW |

~1900kg/h |

~55T |

|||

|

18 |

YDH2000 |

φ2.0×15m |

1100kW |

~2200kg/h |

~60T |

|||

|

19 |

YDH2200 |

Φ2.2×15m |

1300kW |

~2600kg/h |

~70T |

Korean battery new material calcination

Raw material: Lithium iron phosphate material Output: ≥20 tons/day

The project is located in South Korea and is used for the roasting of new battery materials. It adopts electric heating and two-stage series-combined roasting, and then the materials are cooled in a cooler to complete the processing target of this process section. At present, the equipment has been successfully commissioned and put into production.

Production photos