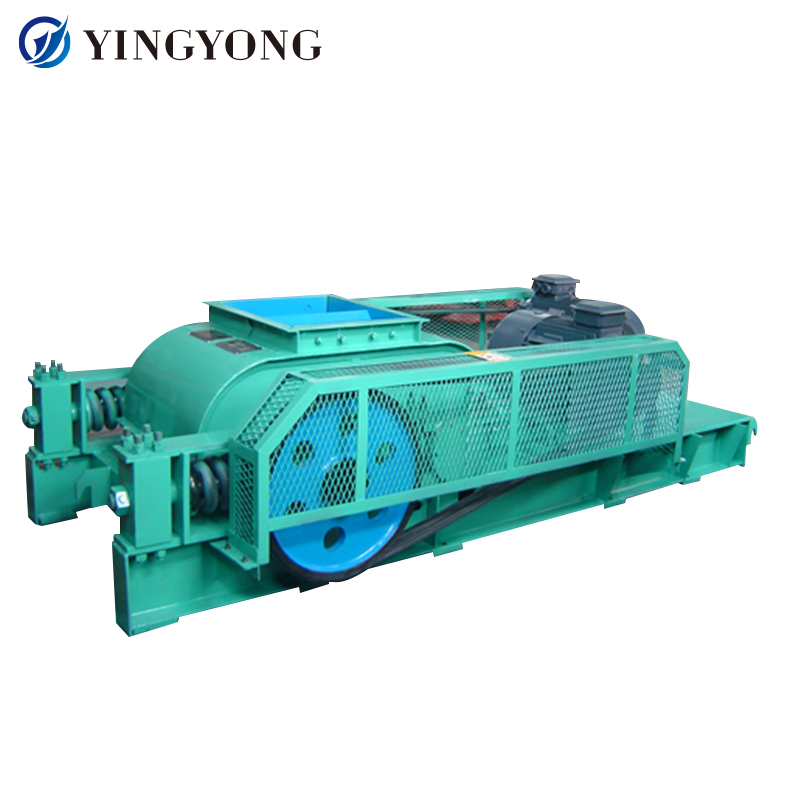

Introduction of Double Roll Crusher

The double roll crusher is specially designed for the fine crushing of limestone.The crusher is equiped with two rollers which rotate towards each other and materials are squeezed, grounded and cut by the shearing force of the rotating roller. When materials enter into the crushing cavity, the materials are subjected to the shearing force of the rotating roller, this causes the materials to pass through the two rollers. At this point, the mineral starts to rupture. The crushed particles move along the tangent direction of the roller, and are discharged through the bottom clearence between the two rollers. Particles that are bigger than the bottom clearance will be crushed continuously until they become small enough to be discharged. It is characterised by high rotation speed of rollers and high capacity. The double roll crusher is also suitable for mineral separation, chemical, cement, building materials industries’ medium and fine curshing of ores and stones with medium and low hardness and compressive strength of not more than 120-150Mpa.

| Model | Roll diameter (mm) |

roll length

(mm)

|

Maximum feed size (mm) | Outlet size (mm) | Roll speed (r/min) |

capacity

(tons/hour)

|

strength

(kilowatt)

|

weight

(Kilogram)

|

||||||||

| C2PGG-400X250 | 400 | 250 | 25-30 | 2-8 | 200 | 3—15 | 7.5x2 | 1300 | ||||||||

| C2PGG-610X400 | 610 | 400 | 35-45 | 45-70 | 2-10 | 10—30 | 60 | 3—16 | 16-49 | 15x2 | 3317 | |||||

| C2PGG-610X610 | 610 | 610 | ≤ 10 | 2-5 | 144 | 16-40 | 2x22 | 4110 | ||||||||

| C2PGG-750X500 | 750 | 500 | 50 | 55 | 75 | 95 | 5 | 10 | 30 | 50 | 50 | 8 | 17 | 49 | twenty two | 6950 |

| C2PGG-900X900 | 900 | 900 | 25-95 | 3-40 | 80 | 10-90 | 2x30 | 16800 | ||||||||

| C2PGG-1000X800 | 1000 | 800 | 25-30 | 5-10 | 100 | 35-70 | 2x45 | 23817 | ||||||||

| C2PGG-1200X800 | 1200 | 800 | 30 | 3-9 | 113 | 26-66 | 2x37 | 21015 | ||||||||

| C2PGG-1200X1000 | 1200 | 1000 | 40 | 2—12 | 122 | 15—90 | 2x45 | 46400 | ||||||||

|

Model

|

Roll diameter (mm) | Roll length ( mm ) | Maximum feed size (mm) | Outlet size (mm) |

capacity

(tons/hour)

|

strength

(kilowatt)

|

weight

(Kilogram)

|

||||||||

| C2PGC-600X750 | 705 | 750 | 300 | 50 | 60 | twenty two | 6950 | ||||||||

| 670 | 750 | 300 | 75 | 80 | |||||||||||

| 635 | 750 | 600 | 100 | 100 | |||||||||||

| 600 | 750 | 600 | 125 | 125 | |||||||||||

| 740 | 750 | 100 | 25 | 30 | |||||||||||

| 715 | 750 | 300 | 40 | 50 | |||||||||||

| C2PGC-600X900 | 705 | 915 | 50 | 25 | 65 | 55 | 7150 | ||||||||

| C2PGC-600X900II | 705 | 900 | 300 | 50 | 65 | 18.5X2 | 6580 | ||||||||

| C2PGC-900X900 | 900 | 900 | ≤ 350 | ≤ 80 | 250 | 55 | 13000 | ||||||||

| C2PGC-900X900II | 950 | 900 | ≤ 125 | ≤ 35 | 90-110 | 110 | 11870 | ||||||||

| C2PGC-850X1500 | 850 | 1500 | 300X1200X1500 | 100 | 100-150 | 2X22 | 27041 | ||||||||

| C2PGC-1200X1500 | 1067 | 1500 | 300 | ≤ 100 | 210 | 110 | 52000 | ||||||||

| C2PGC-1250X1250 | 1205 | 1250 | ≤ 600 | ≤ 35 | 150-200 | 2X75 | 36600 | ||||||||

| 1030 | 1250 | ≤ 600 | ≤ 70 | 350 | |||||||||||

| C2PGT-1400X1400 | 1400 | 1473 | ≤ 800 | ≤ 70(80%) | 300 | 2X132 | 46404 | ||||||||

| C2PGT-1600X1600 | 1600 | 1600 | ≤ 600 | ≤ 30(80%) | 500 | 2X160 | 61807 | ||||||||