Limestone rotary kiln

Limestone rotary kiln

Use of lime

The uses of lime are very wide. Common in construction, building materials, metallurgy, chemical, light industry, environmental protection, medicine and agriculture and many other fields. Especially in steelmaking, ironmaking, sintering, copper, aluminum smelting and other industries, lime as slagging agent, dissolving agent or sintering material

The uses of lime are very wide. Common in construction, building materials, metallurgy, chemical, light industry, environmental protection, medicine and agriculture and many other fields. Especially in steelmaking, ironmaking, sintering, copper, aluminum smelting and other industries, lime as slagging agent, dissolving agent or sintering material

As a kiln for calcination of active lime, with the development of iron and steel smelting technology, the long-term production practice shows that the limestone rotary kiln not only meets the needs of iron and steel smelting, but also fully embodies its superiority in large-scale industrial production and the prospect of sustainable development in other metallurgical industries.

Active lime products are widely used as slagging agent in iron and steel enterprises, especially in converter steelmaking. It plays a very important role in shortening smelting time, improving product quality, optimizing smelting technology and improving economic benefits.

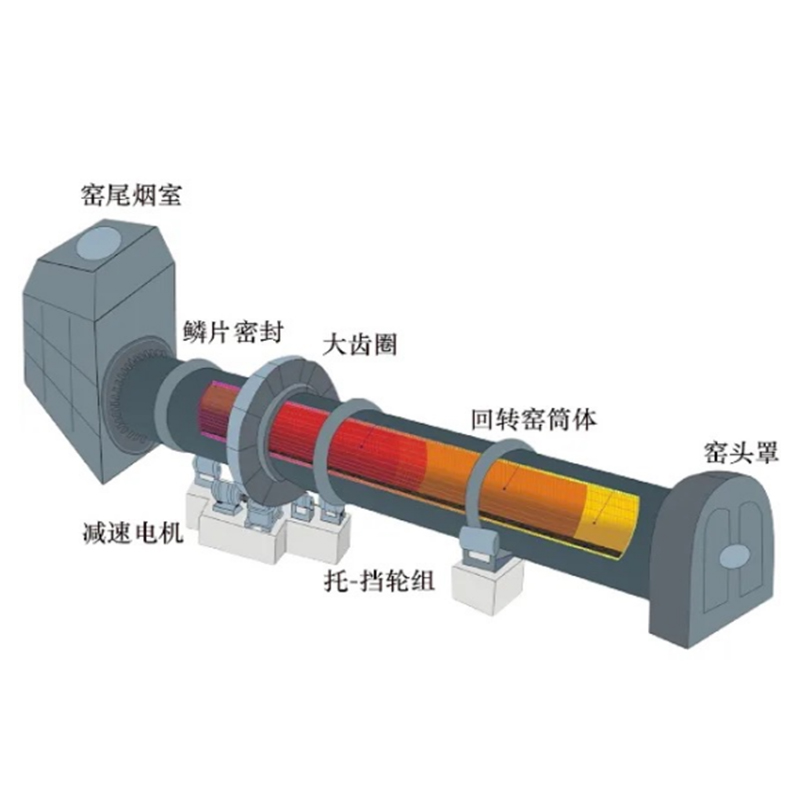

Equipment composition

The dangerous waste rotary kiln is composed of cylinder body, wheel belt, supporting wheel, retaining wheel, transmission device and sealing device of kiln head and kiln tail.

Active lime products are widely used as slagging agent in iron and steel enterprises, especially in converter steelmaking. It plays a very important role in shortening smelting time, improving product quality, optimizing smelting technology and improving economic benefits.

Equipment composition

The dangerous waste rotary kiln is composed of cylinder body, wheel belt, supporting wheel, retaining wheel, transmission device and sealing device of kiln head and kiln tail.

Lime rotary kiln technology

Qualified limestone is stored in the hopper, which is lifted by the hoist and transported to the top hopper of the preheater. The top bin of the preheater is controlled by the upper and lower two level gauges, and then the limestone is evenly distributed to each room of the preheater through the blanking pipe.

The limestone is heated to about 900°C by 1150°C kiln flue gas in the preheater, about 30% of which is decomposed and pushed into the rotary kiln by hydraulic push rods. The limestone is sintered into CaO and CO2 in the rotary kiln. The limestone formed after decomposition enters the cooler, where it is cooled to 100°C by the cold air pumped in and discharged. The hot air at 600°C through heat exchange enters the kiln and the gas is mixed for combustion. The waste gas is mixed into the cold air through the induced draft fan into the bag filter, and then through the exhaust fan into the chimney.

The lime from the cooler is sent into the finished product warehouse by vibrating feeder, chain bucket conveyor, bucket elevator and belt conveyor. Whether to carry out screening and other processes according to customer requirements.

Lime rotary kiln technology advanced, simple structure, low pressure loss preheater can effectively improve the preheating effect, after preheating limestone into the kiln decomposition rate can reach 20-25%, effectively improve the output of rotary kiln, reduce the heat consumption. And can be directly calcined using 20-60mm fine limestone. In addition to the conventional production line, we also have high-end configuration of six pusher preheater, eight pusher preheater, ten pusher preheater, twelve pusher preheater.

Qualified limestone is stored in the hopper, which is lifted by the hoist and transported to the top hopper of the preheater. The top bin of the preheater is controlled by the upper and lower two level gauges, and then the limestone is evenly distributed to each room of the preheater through the blanking pipe.

The limestone is heated to about 900°C by 1150°C kiln flue gas in the preheater, about 30% of which is decomposed and pushed into the rotary kiln by hydraulic push rods. The limestone is sintered into CaO and CO2 in the rotary kiln. The limestone formed after decomposition enters the cooler, where it is cooled to 100°C by the cold air pumped in and discharged. The hot air at 600°C through heat exchange enters the kiln and the gas is mixed for combustion. The waste gas is mixed into the cold air through the induced draft fan into the bag filter, and then through the exhaust fan into the chimney.

The lime from the cooler is sent into the finished product warehouse by vibrating feeder, chain bucket conveyor, bucket elevator and belt conveyor. Whether to carry out screening and other processes according to customer requirements.

Lime rotary kiln technology advanced, simple structure, low pressure loss preheater can effectively improve the preheating effect, after preheating limestone into the kiln decomposition rate can reach 20-25%, effectively improve the output of rotary kiln, reduce the heat consumption. And can be directly calcined using 20-60mm fine limestone. In addition to the conventional production line, we also have high-end configuration of six pusher preheater, eight pusher preheater, ten pusher preheater, twelve pusher preheater.

| Design capability | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 800 | 1000 | |

| (t/d) | ||||||||||||

| product | Activated lime light burnt dolomite | Active lime | ||||||||||

| Rotary kiln | specifications(m) | Φ2.5x40 | Φ2.8x42 | Φ3x46 | Φ3.2x50 | Φ3.5x54 | Φ3.6x5 | Φ3.8x58 | Φ4.2 | Φ4.3x58 | Φ4.3x64 | Φ4.8x68 |

| x50 | ||||||||||||

| Effective volume(m³) | 142 | 190 | 235 | 292 | 390 | 430 | 505 | 575/ | 670 | 738 | 1005 | |

| 548 | ||||||||||||

| Combustion temperature | 1350/ | 1350/ | 1350/ | 1350/ | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | |

| 1250 | 1250 | 1250 |

1250 |

|||||||||

2 production lines of 600 tons of dangerous waste kilns per day in Gansu

Feedback from contact with us

Related Product

Cement rotary kiln

Summary of the equipment

Cement rotary kiln belongs to building materials equipment class, is a kin...

Learn More>

Pellet rotary kiln

Equipment Overview

The pellets are roasted and consolidated in a rotary kiln.

Normal reside...

Learn More>

Rotary kiln

Product introduction

Rotary kiln can be divided into cement kiln, metallurgical chemical kil...

Learn More>