Classification and characteristics

A. Ordinary cement mill Ordinary cement mill is mostly used in the ring flow mill system, which is characterized by high grinding efficiency, mill output, power consumption, especially when grinding slag cement, performance is more prominent. General mill output can be increased by 15-20%, power consumption can be reduced by about 10%, in addition, the finished product temperature can be reduced by 20-40 °C, the fineness of the product is easy to adjust.

B. High fine and high yield cement mill High fine and high yield cement mill is mainly used in open flow grinding system. It is characterized by simple system equipment and process flow, low investment, small factory floor area; In the structure of the mill adopts advanced internal powder special storage device, fine grinding silo increased the activation device, grinding tail has a special discharge grate plate, minimize the size of grinding medium grinding silo, greatly improve the grinding efficiency, to achieve high output, low energy consumption.

| 规格 Spec./m (直径x长度) (Dia.x Length) | 磨机工 作转速 Speed(r/min) | 入料粒度 Feeding Siza(mm) | 生产能力 Capacity(t/h) | 硏磨体装载量 Griding Media Loading (t) | 主电动机 Main Motor (KW) | 主减速机 Main Reducer | 总重量Weight(t) |

| Φ2.2x9.0 | 21.5 | <25 | 14-15 | 39 | 475 | ZD70 | 69 |

| Φ2.2x9.5 | 21.5 | <25 | 14-16 | 41 | 475 | ZD70 | 74 |

| Φ2.2x11 | 21.5 | <25 | 16-18 | 50 | 570 | ZD80 | 109 |

| Φ2.2x13 | 21.5 | <25 | 20-22 | 58 | 630 | ZD80 | 114 |

| Φ2.4x 10 | 20.3 | <25 | 18-20 | 52 | 630 | ZD80 | 108 |

| Φ2.4x11 | 20.3 | <25 | 19-22(开流Open Flow) | 57 | 630 | ZD80 | 116 |

| 22-25(圈流Cycle Flow) | |||||||

| Φ2.4x12 | 20.3 | <25 | 21-23(开流Open Flow) | 63 | 800 | MBY710 | 128 |

| 24-26(圈流Cycle Flow) | JDX710 | ||||||

| Φ2.4x13 | 20.3 | <25 | 22-24(开流Open Flow) | 68 | 800 | MBY710 | 138 |

| 25-28(圈流Cycle Flow) | JDX710 | ||||||

| Φ2.6x11 | 19.7 | <25 | 24-26 | 69 | 800 | MBY710 | 138 |

| JDX710 | |||||||

| Φ 2.6x13 | 19.7 | <25 | 28-32 | 82 | 1000 | MBY800 | 158 |

| JDX800 | |||||||

| Φ3.0x9.0 | 18.2 | <25 | 28-32 | 78 | 1000 | MBY800 | 158 |

| JDX800 | |||||||

| Φ3.0x11 | 18.2 | <25 | 31-35 | 95 | 1250 | MBY800 | 178 |

| JDX800 | |||||||

| Φ3.0x12 | 18.2 | <25 | 32-36 | 100 | 1250 | MBY800 | 182 |

| JDX800 | |||||||

| Φ 3.0x13 | 18.2 | <25 | 33-37 | 108 | 1400 | MBY900 | 190 |

| JDX900 | |||||||

| Φ 3.2x11 | 17.8 | <25 | 40-45 | 110 | 1400 | MBY900 | 215 |

| JDX900 | |||||||

| Φ3.2x13 | 17.8 | <25 | 45-50 | 128 | 1600 | MBY1000 | 230 |

| JDX1000 | |||||||

| Φ3.2x13 | 17.7 | <25 | 50-55(圈流Cycle Flow) | 128 | 1600 | JS120-A | 230 |

| MFY160 | |||||||

| Φ3.2x14 | 17.8 | <25 | 48-53 | 138 | 1800 | MBY1000 | 249 |

| JDX1000 | |||||||

| Φ3.5x11 | 17.1 | <25 | 55-60(圈流Cycle Flow) | 135 | 1800 | JS120-B | 220 |

| MFY180 | |||||||

| Φ3.5x13 | 17.3 | <25 | 60-65(圏流Cycle Flow) | 156 | 2000 | JS130-A | 275 |

| Φ3.8x12 | 17 | <25 | 63-68(圏流Cycle Flow) | 175 | 2500 | JS130-C | 197 |

| Φ3.8x13 | 17 | <25 | 65-70(圏流Cycle Flow) | 190 | 2500 | JS130-C | 245 |

| Φ4.0x13 | 16.3 | <25 | 75-80(圈流Cycle Flow) | 200 | 2800 | JS140-A | 250 |

| Φ4.2x 11 | 15.8 | <25 | 100-110(圈流Cycle Flow) | 195 | 2800 | JS140-A | 248 |

| Φ4.2x13 | 15.8 | <25 | 110-120(圏流Cycle Flow) | 230 | 3150 | JS140-C | 255 |

| Φ4.2x14 | 15.6 | <25 | 120-135(圈流Cycle Flow) | 252 | 3550 | JS150-B | 270 |

| Φ4.2x 15 | 15.6 | <25 | 140-150(圈流Cycle Flow) | 270 | 4000 | JS160-B | 288 |

| Φ 4.6x14 | 15.1 | <25 | 140-150(圈流Cycle Flow) | 285 | 4200 | JS160-C | 320 |

| Φ 4.6x15 | 15.1 | <25 | 150-160(圈流Cycle Flow) | 305 | 4500 | JS160-D | 335 |

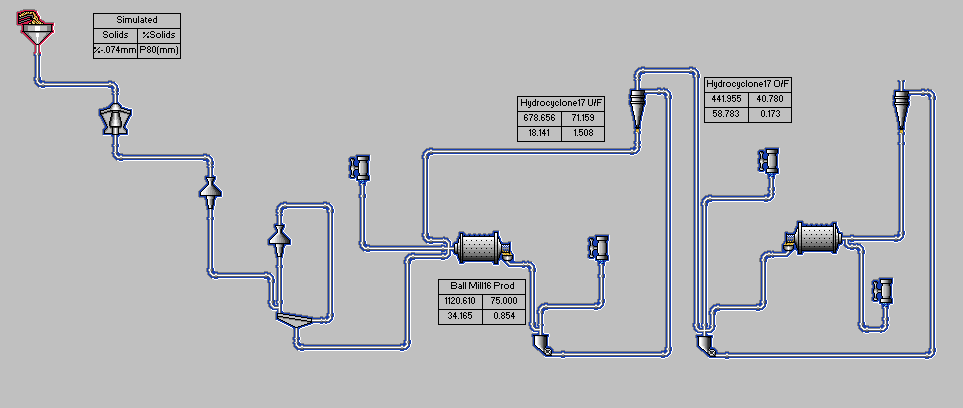

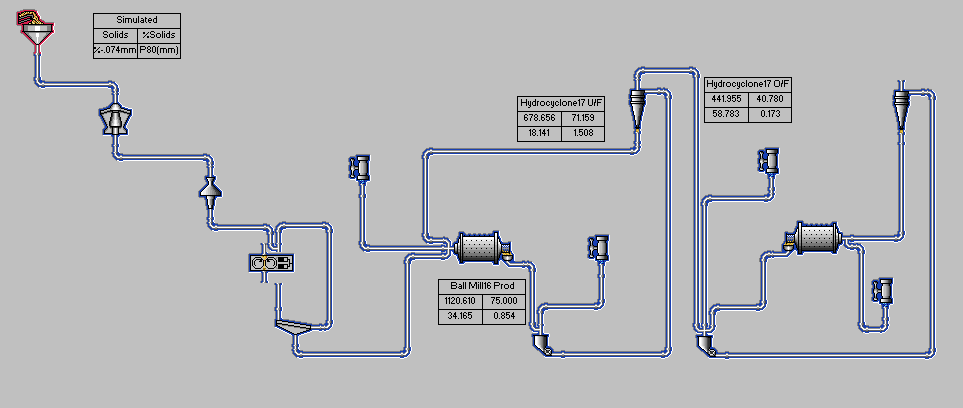

Mineral processing production line is composed of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, concentrator, dryer and other main equipment. The production line has the advantages of high efficiency, low energy consumption, large processing capacity and reasonable economy.

The production process of mineral processing line is: the mined ore is first broken by jaw crusher, broken to a reasonable fineness, by elevator and feeder evenly sent to the ball mill, ore crushing, grinding. The ball mill grinds the fine ore into the next step: classification. The spiral classifier cleans and classifies the ore mixture according to the principle of different specific gravity of solid particles and different precipitation rate in liquid. After a mineral mixture is washed and graded by a magnetic separator, the magnetic and mechanical forces are separated from the magnetic material in the mixture due to the different specific magnetization coefficients of various minerals. After the preliminary separation of magnetic separator, the mineral particles into the flotation machine, according to the different mineral properties of different drugs, so that the required minerals and other substances separated. After mineral separation, because it contains a lot of water, it must be concentrated by thickener and dried by dryer.